Absorbent Glass Mat batteries, or AGM for short, are a type of a sealed lead battery popular in mobile equipment. These batteries are spill-proof and have a number of other advantages, such as high charge and discharge current, good low-temperature performance and moderate price.

But you should also know that AGM batteries are trickier to charge than regular flooded lead-acid types. I recently had to charge a few, and find out that the web is also full of mixed advice on the correct charging voltages and rates, and even on which charger to use for AGM batteries.

Finding reliable information took quite some effort, so I decided to collect it here to my blog. To filter out the unreliable floating around, I chose to base these articles on AGM battery manufacturer data – they at least should have it right.

This first part will look at the fundamentals: AGM charging stages. The second part will give a more detailed account of the AGM charging voltages, while the third will explain the interlinked topics of charging rates, currents and times. Finally, the fourth part will give info on chargers for AGM batteries. I hope that this info may spare your time and AGM batteries! This article contains Amazon affiliate links (Workshoppist.com is an Amazon Associate. As an Amazon Associate we earn from qualifying purchases.)

AGM charging in short

For those in a hurry, I have condensed to how-to part of this article series to a short list. To charge an AGM battery,

- Get a Smart charger with a dedicated AGM mode (see example in Amazon)

- Take the charger and battery to a well-ventilated space close to room temperature

- Set the charger to your battery voltage (6V, 12V, or 24V)

- Set the current to get a 0.1C charge rate (1A for a 10Ah battery, 6A for a 60Ah battery, etc.)

- Select the AGM mode in the charger

- Connect the charger (minding the polarity)

- Wait for around 18h, or until charger indicates, for a full charge

In the best circumstances – the proper charger, a healthy battery, optimal environment and plenty of time – this simple procedure should get your AGM battery charged safely and efficiently.

There is a lot more of depth and detail to AGM charging, though. In these articles, we will take a closer look at AGM battery charging profile and parameters. This will help you in understanding how to charge AGM batteries in varying conditions, diagnose what is going on, and to tune the process for faster charging or best battery life.

AGM battery charging: Standard cycle

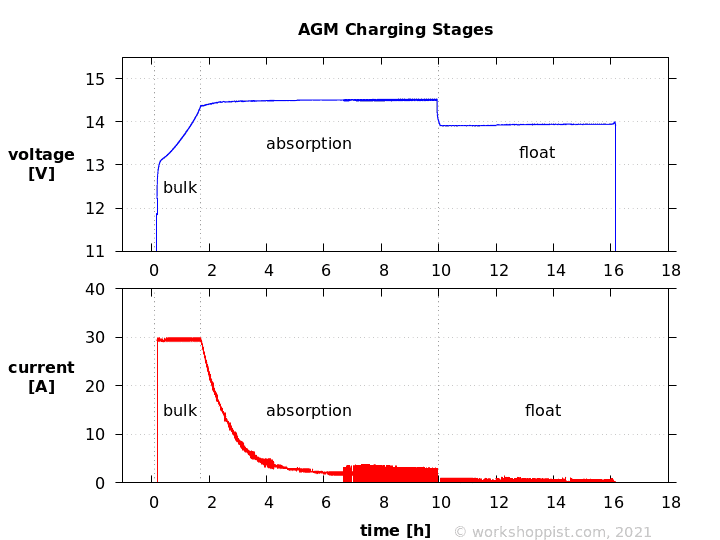

For anyone working with AGM batteries, the first thing to understand is that charging a drained AGM battery happens in stages. The standard charging profile for AGM (and also other lead-acid types) batteries has three stages:

- Bulk charge: Fast high-current charging from a drained initial state up to around 80% of full battery capacity.

- Absorption charge: Slower final charging from 80% to 100% of battery capacity with a constant charging voltage and gradually declining current.

- Float charge: Maintaining the battery at 100% charge with a lower constant voltage.

The first two stages (bulk and absorption) are often referred to as the constant-current-constant-voltage (CCCV) charging cycle. These stages are built into all “smart” chargers and also roughly into regular “dumb” chargers. However, only smart chargers include the the third stage (float).

This standard bulk-absorption-float storage cycle is intended for AGM batteries that are in daily or weekly use; in battery terminology, such batteries are cycled or in cycle use. Which stages are involved in a single charging cycle depends on how empty or full your AGM battery is:

- The entire three-stage charging cycle is intended for AGM batteries that start anywhere between 10% and 80% state of charge.

- Batteries between 80% and 100% start in the absorption stage

- Full batteries go straight to the float stage

The stages are summarized in the table, and discussed each in turn below.

| Stage | State of charge | Voltage* | Charging rate |

|---|---|---|---|

| 1 Bulk | 0…80% | 13…14.5V, rises | 0.1C (normal), 0.2…0.3C fast |

| 2 Absorption | 80%…100% | 14.2…14.9V | declining |

| 3 Float | 100% | 13.2 … 13.8V | very small |

| controlled reference | * for 12V nom. AGM batts. |

Bulk charge: 0% to 80%

Bulk charging is the first stage in charging of a drained AGM battery. In this stage, the battery charger uses a large charge current to bring the battery up to about 80% state of charge in a short time.

The bulk charge happens usually at a constant current determined by battery max rate or charger capacity. A standard “overnight” bulk charge rate for both AGM and flooded-acid batteries is 0.1C, which means a charging current of 6A for a typical 12V, 60Ah car battery. Faster rates of 0.2C…0.3C may also be possible, but come at a cost to battery life.

Note that the charging voltage in the bulk charge stage is not specified as such: a smart charger will set the voltage as needed to achieve the target rate. In practice, the voltage will start from around 13V with an empty 12-Volt AGM battery and rise up to the absorption voltage at the end of the bulk charge phase.

Absorption charge: 80% to 100%

The second stage of AGM battery charging is absorption charge. The purpose of this stage is to take the battery from 80% to 100% state of charge. A smart charger does this by applying a constant high absorption voltage to the battery. The absorption stage is sometimes also called charge acceptance phase or topping charge.

Typical absorption voltage for an 12-Volt AGM battery is 14.5…14.8V, which is slightly higher than for a standard flooded lead-acid battery. The optimal absorption voltage depends on battery brand and temperature, as explained in the next part.

The charging current is declining in the absorption stage. It starts from the full bulk charge current and falls down to less than 1/10 of this rate at the end of the stage. At this point, the battery is full or saturated, and ready for use.

NB: Never hold an AGM battery at the absorption voltage longer than about 15 hours, as this risks overcharging the unit. A smart charger steps down to float automatically; a regular charger must be disconnected.

Float charge: Maintaining 100%

The last charging stage for an AGM battery is float charge. In this stage, the charger maintains a lower float voltage between the battery terminals. The purpose of this stage is not to add any charge, but rather counter self-discharge and keep the battery full.

The proper float voltage for an 12-Volt AGM battery is around 13.5 to 13.8 V, which is slightly higher than for a regular flooded lead-acid battery. The optimal float voltage depends on battery model and temperature, as explained in the next part. The float charge current is very low, and is sometimes called trickle.

Float charge is a maintenance mode and an AGM battery can be kept at float voltage indefinitely. Storage at float voltage holds the battery in good condition and is actually preferable to storing off the charger.

Unlike bulk and absorption stages, float charge is an optional part of the charging process: the float can be omitted without any harm if the battery is needed for use right away.

AGM battery storage charging

Sometimes AGM batteries are not used for some months, or even years. This is the case for vehicles in occasional or seasonal use (motorcycles, boats, snowmobiles) and many backup power systems.

To prevent damage and loss of the unit, AGM batteries should be charged during longer periods of storage at least occasionally. There are three alternative storage charging cycles:

Option 1: Periodic recharge

The simplest AGM battery charging cycle during storage is to let the battery sit disconnected from any load or charger and just recharge it every 6 to 12 months.

The periodic recharging can be done using the standard cycle above. Recharging compensates for self-discharge, and is essential for preventing sulfation and keeping the battery healthy. If omitted, the battery will permanently lose some of its capacity, and may develop dead cells.

The downsides of this storage cycle are the practical inconvenience of remembering to hook up the charger every 6 months, and the inevitable slight capacity fade due to months of storage at not quite 100% charge.

Option 2: Float (better)

A better storage cycle for AGM batteries is to keep them in the float stage for the whole storage duration. This is what battery maintaining chargers have conventionally done.

The float voltage is enough to counter all self-discharge and keeps the battery at 100% all the time. This avoids most of the battery damage associated with storage at a drained state.

The challenge in this method is that using fixed float voltagerisks slight under- or overcharging if the storage temperature varies. Ideally, the float voltage should be adjusted with the battery temperature using temperature compensation.

Some smart battery maintainers and charging systems apply temperature compensation by sensing the ambient or the battery temperature. Close to room temperature the default float voltage should be fine for AGM batteries.

Option 3: Storage Mode (best)

Charger and battery manufacturers have developed various improved combination storage cycles to address the over- and undercharging and gassing issues of single float voltages. These cycles are often called Storage Mode or Maintenance Mode, and are the best option for AGM batteries if available in your charger.

The storage modes are proprietary and vary by manufacturer. However, they usually consist of a long float stages at lowered voltage levels interspersed with brief periods at the absorption voltage. Ctek MXS smart chargers uses a 4-stage storage cycle; Victron Blue Smart uses a 2-stage cycle (links to Amazon).

The lower float voltage at around 13.2V minimizes gassing and the risk of overcharging, but does not quite eliminate self-discharge. The absorption stages bump the battery back to full capacity, but are short enough to avoid overcharging.

While the various storage modes bring more benefit to flooded lead-acid units, they are claimed to improve the service life of AGM batteries too.