Replacing a chainsaw guide bar becomes topical every now and then, as the bar wears and may even be damaged in use. Sometimes, guide bars may be replaced just because you want to swap the bar for a longer, shorter, or a different profile one to change how your saw behaves.

But are all chainsaw guide bars interchangeable? Which bars will fit my saw? – Questions I had two years back when looking for a longer bar for my Makita 2×18 V battery saw. This turned out surprisingly difficult to find out, and I had to learn the hard way that 3/8” and 3/8”P are really different.

Having done quite a bit of research on the topic since, I decided to write this article, where I am going to tell you how interchangeable chainsaw bars are in general and what compatibility depends on. This way, I will hopefully help you avoid my mistakes.

A very short version of the answer is that chainsaw guide bars are usually interchangeable only if they have the same mount type, chain pitch and gauge. In practice, there are several different mounts, pitches and gauges in use even in the saws and bars of a single manufacturer, so that most guide bars mutually incompatible.

Below, I will lay out what all of this means in more detail. First, we will look at why most bars are not compatible. Then we will go through how the mentioned mount, pitch and gauge really vary. After reading this article, you will know what all goes into guide bar compatibility, and how to look for fitting bars.

Are chainsaw bars universal?

A: Chainsaw bars are not universal. Instead, bars are specific to a chain type and have different, incompatible mounts.

More specifically, chainsaw bars vary both in mount geometry as well as in intended chain pitch and gauge, which must match those of your saw and chain. Because of this, you cannot just fit any bar on any saw.

Incompatible mounts

Chainsaw bars have dozens of different mount types, most of which are mutually incompatible. Bar mounts are often brand-specific, so that bars of other brands will rarely fit your saw. Moreover, saw manufacturers would also typically use different mounts in their smaller and larger saws. As an example, Husqvarna uses two and Stihl uses three different mounts, none of which mix well.

Incompatible chain sizes

Bars are commonly made for around 10 different chain pitch-gauge combinations. while not universal, more or less standardized, but there are many of them. This means that you will be able to find plenty replacement bars with the same design pitch and gauge as in your original bar, but must also take care to pick the right one.

Are same brand chainsaw bars interchangeable?

If chainsaw bars are not universal or interchangeable in general, maybe they would be at least within a given chainsaw brand?

Sadly, the truth is that chainsaw bars are rarely completely interchangeable even within a brand. The reason is that most chainsaw manufacturers use two or more mounts and several different chain pitches in their saw lineup.

Which chainsaw bars are interchangeable?

So which chainsaw guide bars then are interchangeable? By definition, replacement bars that are interchangeable with the original bar are those that both fit your saw and take the same type of chain.

As already mentioned, this compatibility is down to three different factors: 1) bar mount, 2) chain pitch and 3) chain gauge. This can be broken down relative to the saw and to the chain:

- To fit your saw, a bar needs to have the same mount type and the same design chain pitch as your saw.

- To fit your chain, a bar needs to be for the same pitch and gauge as the chain; with ready-made chain loops, the chain and bar lengths need to match too.

We will next take a closer look at each of the three areas of compatibility.

Compatibility 1: Bar mount

Most chainsaw bars use a superficially similar arrangement of slots and holes for mounting to the saw body. This arrangement is called bar mount or tail mount. To be compatible, a guide bar and a saw powerhead must have a matching bar mount type.

Bar mount features

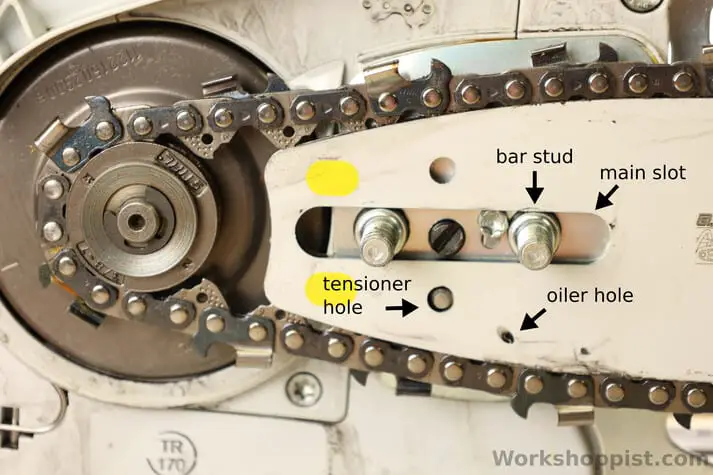

The image below shows the main features of common to practically all bar mounts:

- The main slot to accommodate the bar studs in the powerhead. This is the long slot on the bar center line, and may be open or closed at the end.

- Chain tensioner holes: Smaller symmetric holes on both sides of the main slot. These accept the chain tensioner pin.

- Chain oiler holes: A single small blind hole on both sides of the bar. This hole is located closer to the perimeter, and lets the oil from the chain oiler pass to the chain groove in the bar.

While these features are standard in all chainsaw bars, their size and relative location varies between brands and also product lines of a given brand. Some mounts have a wide main slot, some narrow; some have tensioner holes closer, some further from the main slot – some mounts even have multiple tensioner holes.

The different hole and slot combinations have produced dozens of distinct bar mount types. Sadly, small differences make mounts incompatible: if the holes do not line up, the bar won’t fit or won’t work properly. Because of this, most bar mounts are mutually incompatible. For a bar to fit your saw, the mount types have to be the same, or at least very similar.

Generic mounts and adapters

There are some positive exceptions when a bar can be fitted to a different mount: replacement bar manufacturers like Cannon, Oregon and Sugihara have developed bars with a generic mount geometry that makes them compatible with original bars of many different mount types.

Moreover, many mounts that are not compatible as such can be fitted together using mount adapters. These are available for example from Cannon, and with a bit of machining, you can also make many yourself.

Compatibility 2: Chain pitch

Chain pitch is the length of the links in the chain. To be compatible, a guide bar, the chain and the saw powerhead must all be designed for the same chain pitch.

The reason to this lies in two sprockets: the nose sprocket in the guide bar, and the drive sprocket (also spur sprocket) in the saw powerhead. Both sprockets fit only a single chain pitch, so for the powerhead–bar–chain combination to work, their design chain pitch must be the same.

There are around six common chain pitches: 1/4”, 1/4”P, .325”, 3/8”, 3/8”P and .404”. Small pitch chains are small, and used in low-power battery and under 50 cc gas saws; longer pitch chains are larger overall, and used in bigger and more powerful saws.

Note that the pitches with a “P” suffix (“Picco”, sometimes “LP” or “Mini”) designate special low profile chains and bars. Although the actual pitch is the same, these chains and bars are not compatible with the regular 3/8” or 1/4” chains and bars.

Multi-pitch and adaptable bars

Some are cases when your guide bar does not have to match the pitch of your saw or chain.

The first one is specialty guide bars that have no nose sprocket, and may work with many chain pitches. Examples of such “hard-nosed” bars are many carving bars and Stihl’s Duromatic series.

In other bar models, the nose sprocket or the entire nose is replaceable, and may allow you to fit a nose sprocket of different pitch.

Compatibility 3: Chain gauge

Chain gauge, on the other hand, means the thickness of the drive links of the chain, as shown in the image below. Chainsaw bars have a bar groove in which the lower part of these links run. The chain links should fit the groove snug, but not too tight. For this the nominal gauge of the bar must match that of the chain.

There are four chain gauges commonly in use: .043”, .050”, .058” and .063”. Just as with the chain pitch, you will find the thinner gauges in smaller saws and the thicker in large, high-power saws. Each gauge takes a different width groove in the bar, so that the chain and bar gauges must match.

Four common gauges and six pitches make 4 x 6 or 24 possible pitch-gauge combinations – what a mess for compatibility! Fortunately, chain pitch and gauge go more or less hand-in-hand in practice, so that only 9–10 pitch-gauge combinations are actually in use; I have listed most of them in the table below. Although 10 is less than 24, it is still quite a selection, and means you have to pay serious attention to fitting your bar and chain.

| Chain Pitch | Chain Gauges, common |

|---|---|

| 1/4P | .043” |

| 1/4” | .050” |

| 3/8P | .050” |

| .325” | .058” .063” |

| 3/8” | .050” .058” .063” |

| .404” | .063” |

Note that your saw powerhead does not know (or care) of the chain gauge: the drive sprocket has teeth wide enough to accommodate any gauge chain. Matching gauge is thus an issue of bar&chain only.