Punching your hole centers is an absolute essential for accurate drilling – it is one of the few ways of making sure the drill bit starts where you intend it to. Traditionally, this task has been achieved with a manual punch and a hammer, but there is a smarter alternative: an automatic center punch.

With its internal striking mechanism, this small ingenious tool avoids the hammer and makes the punching process much more convenient. With a history of over 100 years, the automatic center punch is by no means a novelty. Yet this tool is small and unassuming, and easily mistaken for a manual punch by an untrained eye. Consequently, it is not know to all hobbyists and beginner metalworkers.

In this article, I will introduce you to automatic center punches and go through everything you should know about them: what are they, how to use them, how they work, and why would you want to use them. Whether you are looking to improve your drilling accuracy or just extending your knowledge, the information below should prove helpful.

What is an automatic center punch?

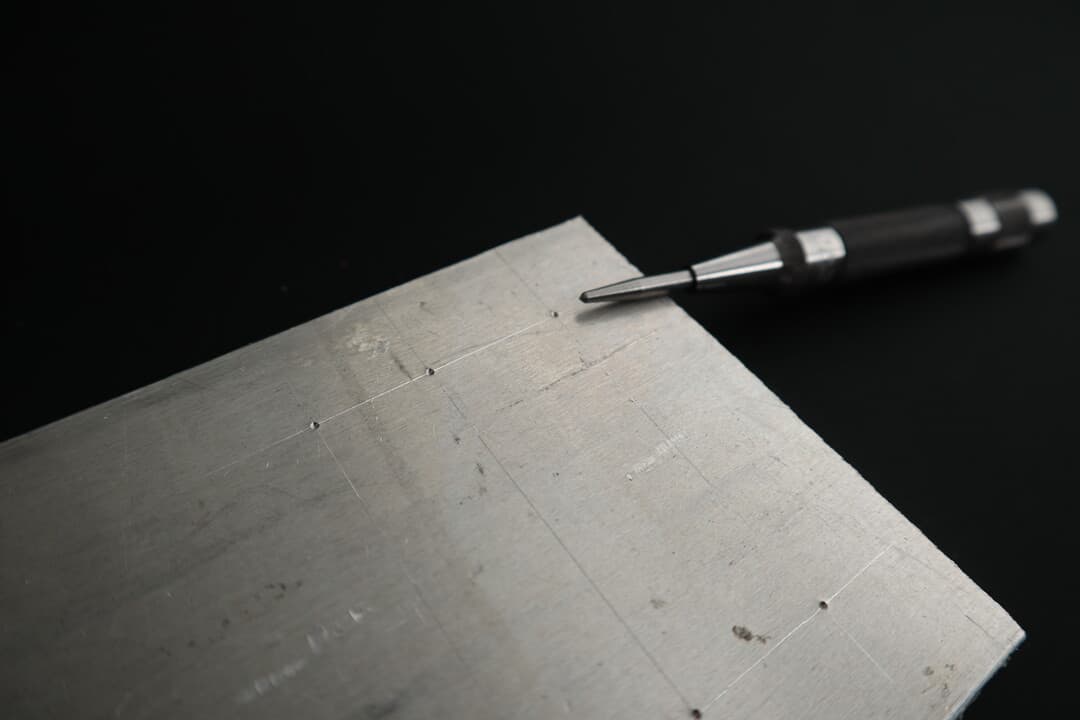

Simply put, an automatic center punch is a conical-tipped punch that contains an internal striker mechanism. It allows you to mark and dimple centers onto workpieces without using a hammer.

The automatic center punch is of roughly the same size and shape than a manual center punch. However, it differs clearly from manual punches in its construction, and can be identified on the following differences in appearance:

- The tip of the automatic punch is more slender than that of a manual punch

- The tip is now a part of an mobile assembly, and can slide in and out of the main body

- The main body is always round and not hexagonal as usual in manual punches

- The main body is knurled or rubberized to allow you to push it down while loading the spring

How to use an automatic center punch?

Using an automatic center punch is extremely simple:

- Place the punch tip onto the spot where you want to punch

- Press the the punch down against the workpiece

As you push, the punch will first yield, and then snap back sharply, creating a dimple in the workpiece. The whole process is very fast and takes only a second or so.

You may repeat the process a few times if you want to increase the dimple depth. If you choose to do so, be sure to check that the punch tip stays in the same place and does not bounce off the dimple between the strikes.

How does an automatic center punch work?

But how is the automatic center punch actually able to deliver the sharp knock when you just press it down? The answer is that it uses one of a number of rather clever mechanisms which store energy from the push of your hand to a spring, and then release it abruptly.

On a more detailed level, the internal mechanics work roughly like this in all variants:

- When you bring the punch tip into contact with the workpiece and start pressing down, the tip actually starts compressing one or more springs inside the punch body

- Once you have pressed deep enough, a trigger mechanism quickly decouples the tip from one of the springs, and directs the force of the loaded spring instead to a mobile hammer mass

- The hammer mass is rapidly accelerated by the spring force, and is free to travel for a distance inside the punch body.

- After a short travel, the hammer comes to a hard stop against the upper end of the punch tip. This gives the tip a powerful jolt, and drives it into the workpiece, creating the desired dimple.

What makes the automatic center punch really handy is that all of this happens in a single process without you having the push any buttons, throw levers, or the like – all you have to do is push the punch against the workpiece, and the mechanism will take care of the rest.

Advantages of automatic center punches

So why would you exactly want to use an automatic center punch instead of a manual one?

The main reason is that, compared to a manual punch and a hammer, an automatic center punch is faster and more convenient to use and more compact to carry around.

Whereas manual punching requires you to use two hands and two different tools simultaneously, an automatic center punch can be operated with a single hand. This lighter punching process improves your overall productivity and lowers the strain on your hands, which is important particularly in large repetitive drilling tasks.

Perhaps the biggest advantage of an automatic center punch is still the fact that you do not need a hammer to drive it. This may not sound like a big deal, but the difference is actually quite significant in practice: the automatic punch will fit your shirt or coat pocket, following you everywhere you go in the shop. The hammer is too large to do the same, which forces you to fetch this tool each time you want to punch, carry a tool box around, or have a hammer at hand at all stations where you are marking up workpieces.

A further advantage that the automatic punch can claim is consistency and repeatability of the dimples it produces. With a manual punch the dimple will vary depending on how hard you happen to tap the punch each time, and although pretty consistent results can be obtained, this requires some skill and concentration. The automatic punch, on the other hand, will regulate the impulse itself, relieving you of this task.

The traditional manual punches do have some advantages over automatic center punches. For the first, manual punches do not need to contain any moving parts or mechanisms, and are therefore more robust and affordable than automatic center punches.

Manual punching with a hammer also allows the operator to modulate the punching force faster and over a wider range than an automatic center punch. Resetting the automatic punch impact force takes some time, and the force can be made to vary only within a relatively narrow range – it does not allow very light or very heavy impacts. The manual punch, by contrast, can be driven just as gently or hard as the operator pleases, and the force changed from strike to strike. The wide range force modulation is particularly important with hard materials, where a standard punching force may not produce enough of a dimple to securely guide a drill bit.

How to adjust an automatic center punch?

Many automatic center punches allow you to adjust the impact strength. In most models, you can do this by simply rotating a knob at the end of the punch. The impact strength will usually increase by rotating the knob counter-clockwise, and decrease by rotating it clockwise.

This knob controls the impact force by adjusting the pre-stress in the hammer spring inside the punch. The higher the pre-stress, the stiffer the punch is to load and the stronger the delivered impulse will be.

Lowering the impulse strength will make the dimple smaller and the punch lighter to operate; increasing the impulse strength has the opposite effects. As a general rule of thumb, the harder your workpiece material and the larger the drill bit you are going to use, the higher the punch force should be.

The impulse force adjustment in automatic punches rarely has any scale, and no information is usually available on the minimum and maximum forces. The force adjustment is therefore best done by trial and error. Hardened steel will usually require the highest force setting, while aluminum and wood are sufficiently marked already at lower forces.

How much do automatic center punches cost?

Automatic center punches are not particularly cheap. A standard model from a quality manufacturer such as Starrett or Hazet typically sells at around $30, and is therefore many times the price of a set of manual punches. Larger heavy-duty automatic center punches may cost as much as $50.

That said, automatic center punches are not very expensive either. Regardless of which punch model you buy, it will be cheaper than a quality set of coated or cobalt alloy drill bits, not to mention the drill press you are using. Unlike the drills, the automatic center punch will also not wear out very fast.

Conclusion

As we have seen, automatic center punches are compact, easy to use and not terribly expensive alternatives for manual center punches. While some workers still prefer manual punches, the wide adoption of automatic center punches in workshops bears witness to the benefits they offer.

Personally, I prefer to use an automatic punch for all but very heavy punching tasks. Although they are not exactly cheap compared to manual punches, I think an automatic center punch adds enough value to justify its cost in all but very infrequent use.