Bandsaws are really useful tools and often the cornerstone of a woodshop, but the bandsaw sizing system is a source of much confusion. And no wonder: the nominal “inch-size” of a bandsaw is neither a functional dimension nor something you can see on the outside of the saw. In plain language, nothing you see on a 14-inch bandsaw is 14 inches.

Yet bandsaw sizing is something you should understand if you own a bandsaw or are planning to get one. In this article, I am going to explain how bandsaws are sized and how the bandsaw cutting capacity, outer dimensions, and price depend on the saw nominal size. We will also go through some guidelines for selecting the right bandsaw for your use. I have also included some product links to Amazon (Workshoppist.com is an Amazon Associate. As an Amazon Associate we earn from qualifying purchases.)

Bandsaws come in three to four different formats, and before we start, I should emphasize that we will here focus on stationary vertical-cutting bandsaws for woodworking and metalworking; these are the type that most likely comes into your mind from the word ‘bandsaw’. The other bandsaw types – portable and stationary cut-off bandsaws and milling bandsaws – differ in sizing from the traditional woodshop bandsaw, and deserve a separate discussion.

How is bandsaw size defined?

So what in a 14-inch bandsaw is 14 inches? If you are shown a 14-inch saw, it is immediately obvious that its not the height or width. Maybe the length?

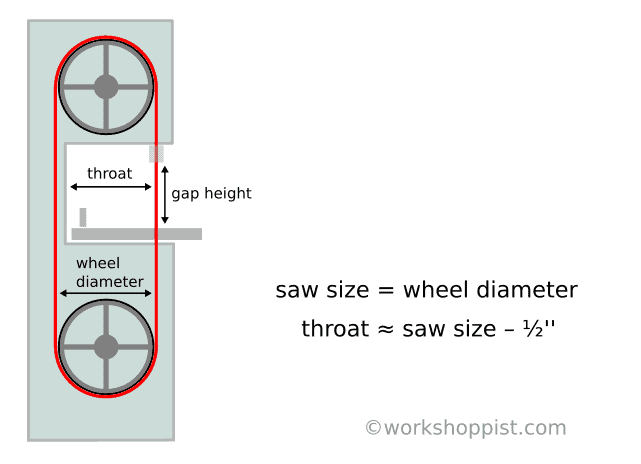

The truth is that nothing in a 14-inch saw visible to the outside is exactly 14 inches. Instead of the outer dimensions, the size of a bandsaw is defined by the diameter of the drive and idler wheels inside the machine. These wheels are what the blade of the saw runs on and therefore a central component of the saw.

The wheel diameter is not a functional dimension, nor apparent from the outside. Why are bandsaw sizes defined through this diameter then?

The answer is that wheel diameter is the central constructional dimension of the saw, and roughly determines the cutting capacity and physical size of the machine.

To understand how, take a look at the drawing above. It shows a minimal bandsaw without covers. You see that:

- The height of the saw is at least two wheel diameters plus the gap height.

- The width of the saw is at least one wheel diameter

- The maximum cutting width is one wheel diameter at a maximum

Common bandsaw sizes

9 inch (230 mm)

The bench-top bandsaw: powerful enough for many small jobs, and light enough (~ 40 lb.) to be lifted and stowed away when not in use. Maximum cut height usually limited to 3½”; low motor power (~1/3 hp) means that cuts will be relatively slow. An example of a 9″ band saw here (link to Amazon).

10 inch (250 mm)

A transitional size including both bench-top and floor-standing models. Slightly more average cutting capacity and power than in 9-inch saws, but also substantially more weight: at 70 to 80 lb., most 10-inch bench-top models are not convenient to lift on and off the bench all the time. See an example of a 10″ band saw here (link to Amazon).

14 inch (350 mm)

A very popular medium bandsaw size, considered by many as the first “serious” band saw. All models are floor-standing, with the saw table brought to a convenient working height with a closed or open frame stand. Cutting capacity often in excess of 10 inches, and may allow resawing at moderate rates. Weight of 150 to 350 lb means that 14-inch bandsaws are movable mainly on castor wheels. See example of a 14-inch band saw here (link to Amazon).

18/19 inch (450 mm)

Large floor-standing shop saw suited for professional use. A several-horsepower motor and vertical cutting capacity of around 15” allow resawing, and are more than enough for typical sheet good and lumber work. Due to their substantial weight (300…800 lb.), 18-inch bandsaws are best kept in one place. See example of a 18-inch band saw here (link to Amazon).

Other sizes

Bandsaws are available in many intermediate sizes between the common ones. You should be able to find at least 12-inch and 15-inch saws, and perhaps some 13” and 17” models. While I would in general recommend to stick to the common sizes (due to blade availability), these intermediate sizes may sometimes offer a sweet spot for your work profile in terms of capacity, size and price.

Bandsaws also come in sizes below 9” and above 19”. On the small side, 8 inches (200 mm) is a popular alternative size in Europe. There is much more variety in large saws, with many models available in sizes of 20”, 21” and 24”. With a price tag of several thousand dollars and weights approaching 1000 lb, these large saws are best suited for professional use.

Cutting capacity and saw size

Bandsaws have many characteristics, but the most important numerical specifications can be boiled down to three: throat, gap height and power.

These specifications vary with saw size. Below, you will find a useful table that show typical throat, gap height and power specs for four common bandsaw sizes. I have assembled the data from the current offering of General Industrial, Genesis, Grizzly, Jet, Powermatic, Record Power, Rikon, Ryobi, Shop Fox and WEN.

| Wheel Diam. | Throat | Gap height | Power | Size |

|---|---|---|---|---|

| 9” | 8-3/4” | 3½” | 1/3…½ hp | bench- top |

| 10”…12” | 9-3/4” | 4…6” | ½…2/3 hp | floor |

| 14” | 13-3/4” | 6…14” | 1…2 hp | floor |

| 18″(19”) | 17-3/4” | 12…16” | 2…5 hp | floor |

We will next go through what these three specs really mean and why they matter.

1 Throat

The throat of a bandsaw means the sideways distance of the saw blade from the frame. The throat is a very important dimension, since it determines the maximum cutting width of the saw, i.e. the width of workpiece that fits on the left-hand side of the blade. The throat may be also called cutting capacity (width), horizontal cutting capacity or just maximum cutting width.

The throat of most bandsaws is equal to the saw nominal size, i.e. the wheel diameter, minus a small blade clearance between 1/4” and ½”.

2 Gap height

The gap height of a bandsaw means the maximum free height of exposed blade in the gap between the saw table and the upper blade guide. This central dimension determines the maximum cutting height of the saw, that is the tallest cut you can make with it. The gap height is also called vertical cutting capacity, cutting capacity (height) or cutting height.

Unlike the throat dimension, the gap height is not directly determined or limited by the saw wheel size.

NB: In most band saws, the upper blade guides which limit the gap are riding on an adjustable guide post. The maximum gap height of a saw is therefore measured from the table surface to the upper blade guides when the guide post is raised to its upmost position.

3 Power

The saw power means the saw motor electrical power rating (A or W) or the shaft power (hp or W). The saw power is important in that it determines maximum cutting rate, i.e. how fast the saw can cut when you push it. In practice, the saw power also often limits the maximum cutting height.

Size, Weight and Cost

When it comes to cutting capacity, there is one simple rule: the bigger the bandsaw, the better. However, you will have to pay a price for all of this in terms of the physical size, weight and cost of the saw.

Larger bandsaws are more capable, but also bigger, heavier and more expensive than small ones. As your shop space and budget are often limited, you should consider these practical aspects when choosing a bandsaw for your shop.

| Wheel Diam. | Height | Footprint | Weight | Price |

|---|---|---|---|---|

| 9” | 29”…30” | 20” x 13” | 30… 45 lb | $125… $250 |

| 10”…12” | 33”…60” | 21” x 16” | 75… 150 lb | $250… $700 |

| 14” | 64”…77” | 32” x 28” | 170… 350 lb | $750… $1350 |

| 18/19” | 73”…87” | 36” x 32” | 350… 800 lb | $1500… $4000 |

The table above lists typical height, weight and price of bandsaws of four common sizes. In the table, we see that:

9-inch bandsaws are small, bench-top machines, light enough to be lifted away for storage, and yours for one to two hundred dollars. When not in use, a 9-inch bandsaw will handily fit under a standard-height workbench. These set minimum space and money you have to invest to a bandsaw.

10- to 12-inch saws, on the other hand, come both in bench-top and floor-standing configurations. In both formats, they weigh already around 100 lb., and are no longer convenient to move around often. This means that 10- to 12-inch saws will most likely require a permanent position on your bench or your shop floor. Money-wise, you will have to pay anywhere from a few hundred to seven hundred dollars for these saws.

14-inch bandsaws are always floor-standing and require a dedicated spot on your shop floor. At a few hundred lb. in weight, they are too heavy to move without rollers, and may take some planning to bring to workshops without ground-level access. A 14-inch band saw from reputable manufacturers will cost you around $1000, give or take a few hundred.

18-and 19-inch bandsaws are massive, and without a doubt one of the biggest machines in your workshop. These saws will take 3 x 3 ft. (1 x 1 m) of floor space and the most of room height. With these saws, you will not only have to check how you get the saw into your workshop, but also if the floor is rated for their 400 to 800 lb. weight. For these machines, you will have to invest a few thousand dollars.

In general, bandsaws are big and pricey tools. They are definitely larger and more expensive than handheld alternatives such as jigsaws, circular saws and track saws. They are also taller and less portable than contractor table saws with similar power.

How to measure bandsaw size?

The easiest way to find out the size a bandsaw is to check the nameplate – the saw size is often a part of the model name or separately indicated there.

If no marking of the size cannot be found on the saw, you will have to measure it. Fortunately, determining band saw size is fairly straightforward.

Method 1: Measure the throat

You can get a rough estimate of bandsaw size quickly by measuring the saw throat dimension and rounding it up:

- Measure the sideways distance of the saw blade from the frame

- Round the measurement up to full inches

This method is based on the fact that the throat dimension of the saw, which you are measuring here, is almost always very close to the saw size.

Method 2: Measure the wheels

For a more accurate and reliable result, you can open either of the saw wheelcases and measure the wheel diameter which actually defines the saw size.

- Make sure the saw blade is stationary

- Unplug the saw from power

- Open the upper or lower wheelcase

- Measure the band wheel diameter

- Close the wheelcases

- Plug the saw back in

What size bandsaw should you buy?

The answer to this question depends on the type of work you do and the resources you can allocate to the saw. Bandsaw size choice is a compromise between cutting capacity and features on one hand and size, weight and price on the other. I have here condensed the choice to four principles:

Principle 1: Bigger is better

For best results and widest applicability, get the biggest saw you can afford and have space for. An 18-inch or larger saw can do all narrow, wide, short and tall cuts, and do them faster and with more precision than a small 9-inch saw can. A large saw can both resaw logs and cut fine details into sheet goods, and is just nicer to work with than a small saw.

Principle 2: Fit for purpose

If your budget or shop space is limited, get the smallest bandsaw that can get most of your work done. What this means in practice will vary a lot from one woodworker to another, but some guidelines can be given:

- If you are mostly working with small decorative items and thin sheet goods below 1”, you are likely going to be just fine with a 9-inch band saw.

- In case you do not own a table saw and want to use the band saw occasionally for ripping short boards, consider a 10” band saw with a ½ hp motor – it is not fast, but will get the job done

- If you want to do some resawing, 14” is the practical minimum. While a 10” saw will technically have enough vertical capacity for resawing small stock like a standard 4” board, the low motor power will make even this cut impractically slow.

Principle 3: Derate vertical capacity

When judging which bandsaw size has enough capacity for your work, avoid the pitfall of taking the specified gap height or vertical cutting capacity at face value. A case in point is the standard 9-inch bandsaw, which has 3½” vertical cutting capacity. This sounds like plenty – all sheet goods and furniture lumber should be good, right?

And technically yes, the small 9-inch saw can cut them. But in practice, due to the limited motor power the cut will proceed so slow that you do not want to be making 3” high cuts with a 9-inch band saw all that often. Indeed, a practical upper limit for stock thickness is usually around 1/3 of the specified gap height.

Principle 4: Consider alternatives

Getting a bandsaw that can do all of your cuts easily leads to overkill. It is good to remember that other saws exist too, and are often better than a bandsaw at its capacity limits. Here are a few common cases:

- Straight cuts into sheet goods: leave these for the circular saw or the track saw – they have no horizontal capacity limits and will cut cleaner and straighter than a bandsaw

- Curved cuts into sheet goods: use a jigsaw. A jigsaw has no horizontal capacity limits and cuts both small and large pieces easily.

- Ripping lumber: this is better done with a table saw. Table saws cut faster and more precise and leave a smoother surface finish. See my comparison of bandsaws and table saws for more info.

A bandsaw is at its best with small workpieces, multi-material workpieces, with intricate curves and in resawing. It is wise to size your bandsaw with these applications in mind, and leave large sheets, for example, to other saws.

Application profiles

Let us then briefly look at the application profiles of different size bandsaws. The table below summarizes my view of the capabilities of each of the standard bandsaw sizes.

| Band saw size: Application: | 9” | 10” | 14” | 18” |

| decor | + | ++ | +++ | +++ |

| furniture-making | – | + | ++ | +++ |

| ripping lumber | – | + | + | ++ |

| resawing | – | – | + | ++ |

Blade size and saw size

Bandsaw blade sizing is a topic in its own right. But as it is closely related to bandsaw size, we will next take a quick tour of bandsaw blade sizes and how they vary with saw size.

Bandsaw blades are defined by four central dimensions:

- Length

- Width

- Thickness

- Teeth-per-inch (TPI)

In general, bigger saws take blades that are longer, wider and thicker than those for small saws. The relationship of blade and saw sizes is more nuanced that this, and has many important aspects that you should understand when getting a new blade for your saw. We will next go through these.

| Saw size (Wheel diameter) | Blade length | Blade width min | max |

|---|---|---|---|

| 9” | 59½”…62” | 1/8” | 1/4”…3/8” |

| 10” | 67½”…72” | 1/8” | 1/2” |

| 14” | 93”…120” | 1/8” | 3/4” |

| 18/19” | 140…168” | 1/8” | 1”…1-1/4” |

1 Length

Each bandsaw has a clearly defined blade length that it accepts. This derives from the fact that the blade runs and must be tensioned on the two band wheels of the saw, which have only little capacity for height adjustment. Blades that are too short cannot be pulled onto the wheels; ones that are too long cannot be tensioned.

Nominal saw size is part of what determines the proper blade length for a bandsaw. However, the proper length is also affected by an another parameter: the distance between the wheel centers. This dimension related to the gap height may vary substantially between saws of the same nominal size. Because of this, two band saws of the same size may take very different length blades.

This is illustrated in the table below, which shows the common blade lengths for band saws of four standard sizes. While the blade lengths clearly increase from the around 60” of 9-inch saws to the 150” for 18-inch saws, they also vary a lot within a given saw size. The blade lengths of 14-inch saws, for example, vary from 93” to 120” – a 27-inch range. Saw size alone does not tell the proper blade length.

How to determine the proper blade length?

To find out the blade length that fits your bandsaw, you can:

- Check the blade length from the saw specifications

- Measure the length of the old blade. This is best done with a flexible tape measure and the blade lying unfolded on a table.

- Measure the distance between wheel centers. Together with the wheel diameter, this distance can be used to calculate the proper blade length using the formula L = 3.14*D + 2*CD, where L is the blade length, D the wheel diameter, and CD the distance between centers.

2 Width

Most bandsaws take blades of different widths. Unlike the blade length which needs to be exactly right, the blade width can vary between a minimum and a maximum specified for the saw.

The minimum blade width for most standard band saw sizes is 1/8”. These very fine blades allow cutting tight curves and have a narrow kerf.

The maximum blade width varies with saw size. Most 9-inch band saws take blades up to 1/4” or 3/8” wide, 10-inch saws up to ½” wide, 14-inch up to 3/4” wide, and 18/19-inch saws up to an inch or a bit more. These wide blades are stable even under a large thrust and great for straight cuts near the capacity limits of the saw.

3 Thickness

Band saw blade thickness is also connected to saw size: bigger saws are able to take thicker blades than small ones. This is thanks to the larger radius of the band wheel, which requires the blade to bend less, so that even thick and stiff ones are able to around without excessive strain. Thick blades are useful in that they are more stable and cut very straight.

The majority of bandsaw blades for woodworking are .025” or 1/40 in. thick; it is the standard thickness for most saw sizes. However, thinner .014” to .020” blades may be better for small 9- and 10-inch saws, and large bandsaws are able to take blades thicker than the standard .025” for heavy applications.

Bandsaw size Q&A

Which bandsaw size for resawing?

Answer: I recommend 14” and upwards.

Resawing needs both a high vertical cutting capacity and plenty of motor power. Small 9” or 10” band saws have gap height to allow cuts 3” to 4” high at a maximum, and will typically struggle to make even these at a decent cutting rate due to the low motor power. While technically possible, resawing with these saws is quite limited, slow and not productive at all.

Bigger saws 14” and above have often more than 10” of gap height and one or several horsepower motor. These saws will allow you to resaw typical sized pieces of log or lumber into boards or veneer.

From the 14” saw selection, you should prefer special, high-gap and high-power models. These are often termed “resaw bandsaws” – these will have 13…14” of vertical capacity and 2 hp of power.

At sizes 18” and larger, pretty much all models have at least 12” of vertical capacity and 2 hp of power, and any saw of this size should be fine for resawing.

Which bandsaw size for woodworking?

Answer: This question is practically the same as the more general one “What size bandsaw should you buy”, and is addressed above.

What size blade will a xx inch bandsaw take?

Answer: The saw size does not alone determine the blade length. For ways to find out the proper blade length to your saw, see the section blade length above.

Which size bandsaws are below $500?

Answer: 9-inch and 10-inch bandsaws are generally available under $500; 14-inch saws start at around $700. See the Size&Price table above.