Band saws and table saws are two of the largest saws you are likely to own as a hobbyist, or even as a professional woodworker. Given the substantial investment of money and workshop space you have to dedicate to either of them, you might be wondering whether you really need both of these large saws? Could I get away with one, and would that be the band saw or the table saw?

In this article, I will compare band saws and table saws – their cutting performance, other properties, and preferred applications – with the aim of helping you answer these questions for yourself.

The synopsis of the comparison, in a very condensed form, is:

Table saws excel at making highly accurate smooth straight cuts at high speed into workpieces of all sizes; as such, it is the better choice for resizing lumber and cutting sheet goods into dimension in construction, remodeling and modern cabinetry.

The band saw can do both straight and curved cuts at medium accuracy, cut quality and speed, into small-to-medium sized workpieces of different materials stably and safely. It is the better choice for traditional and decorative carpentry and for very small workpieces.

Next, we will start by going through the performance and properties of the saws in the following categories:

- Cutting capacity: cut height, workpiece width, speed

- Cut geometry: cut line, blind cuts, stopped cuts, kerf

- Cut quality: dimensional accuracy, surface finish

- Practical considerations: safety, noise, dust extraction, multi-material, size, footprint, cost

After this, we will consider the suitability of band saws and table saws in different application fields, and finally take a quick look at their relation to other saws. For those in a hurry, the essential is summarized in the table below.

| Category | Property | Band saw | Table saw |

|---|---|---|---|

| Cutting capacity | cut height | 2”…10” | < 4” |

| workpiece width | limited LHS | unlimited | |

| speed | lower | higher | |

| Cut geometry | curved cuts | yes | – |

| blind cuts | – | yes | |

| stopped cuts | yes | – | |

| kerf | ~.05” | .08” … .10” | |

| Cut quality | dimensional accuracy | + | +++ |

| surface finish | + | +++ | |

| Practical | safety | safer | less safe |

| noise power level | quieter | 100…110 dB(A) | |

| dust | cleaner | messier | |

| multi-material | easy | difficult | |

| size | larger | smaller | |

| footprint | same | same | |

| cost | $100…$3000 | $350…$3000 | |

| Applications | trad. furniture resawing decor prototyping | construction resizing lumber sheet goods remodeling |

1 Cutting capacity

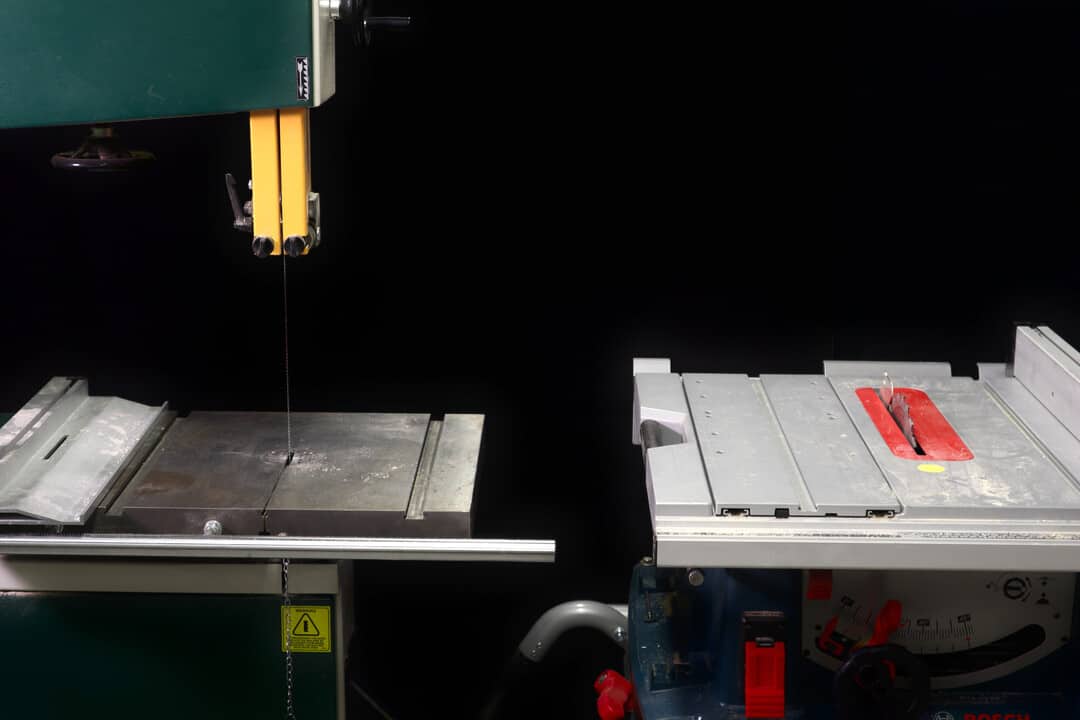

Band saws and table saws differ substantially in cutting capacity: cut height, workpiece width and cutting speed.

1.1 Cut height

Standard-sized portable job site and workshop table saws have a maximum cutting height of 4” (100 mm) or slightly less, limited by the blade diameter. This height is quite sufficient for cutting all sheet goods and the majority of lumber resizing, but may not be enough for resawing boards or cutting veneer. In practice, most job site table saws will allow you to narrow down 1×4’s and 2×4’s, but splitting a 4×4 in a single cut will be possible only with the largest models.

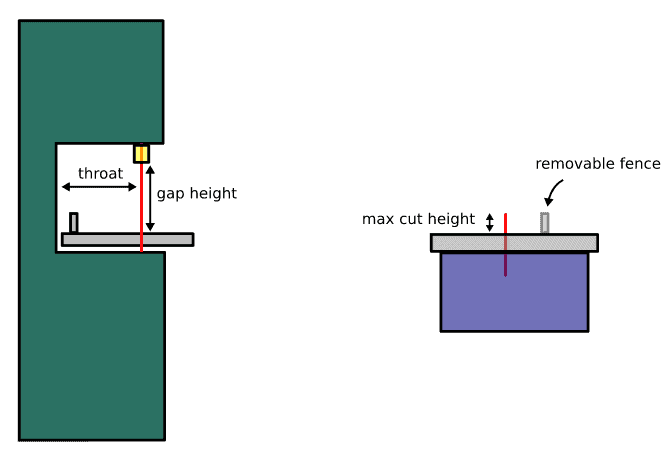

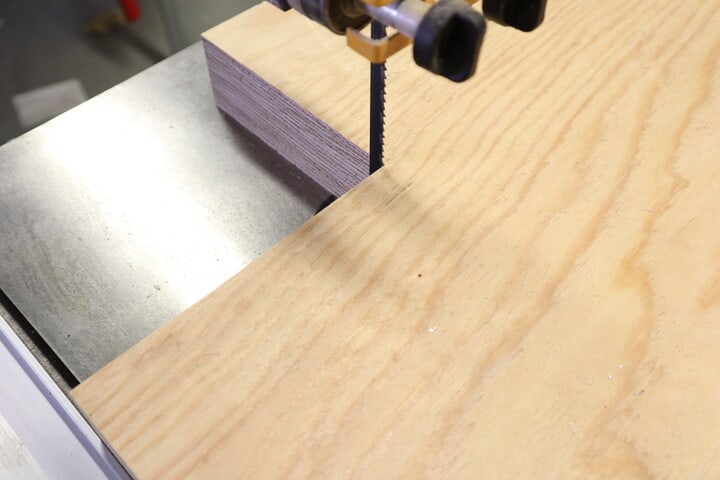

Band saws can cut significantly higher stock than table saws. The cut height in a band saw is ultimately limited by the height of the frame opening, illustrated in the image below, which for a typical large floor-standing model is between 8” and 12”.

However, using the full opening height for a cut will limit you to impractically slow cutting speeds with most band saws due to the limited power and stalling. But even with this limitation factored in, a large band saw will still have around twice the useful cutting height of a table saw, allowing resawing of most lumber as well as sawing rough wood.

1.2 Workpiece width

Table saws can handle workpieces of any length or width. Cutting very long or wide workpieces on the table saw may require removing the fence and providing additional supports for the workpiece, there are no real limits to how large pieces can be cut on the table saw. The maximum rip width which you may see quoted on many table saw specifications refers to the maximum width that you can cut still using the fence.

Band saws, by contrast, have a definite limit for cutting width: the part of the workpiece on the left-hand side of the cut must fit between the blade and the machine frame. This sideways distance of the blade from the nearest point on the machine frame is called the throat (see image above), and is usually between 15” and 24” for large floor-standing models. The widest strip you can cut is equal to the throat, and if you want to use the fence, to a bit less than that.

These width limits mean that table saws are well-suited for cutting sheet goods, where the strips may be quite wide, and can also be used for cross-cutting long boards, provided adequate supports. Band saws, on the other hand, are quite restricted in working with sheet goods, and almost useless in cross-cutting.

1.3 Speed

Table saws usually have clearly more power than band saws of similar size, which makes them faster cutters.

To make the difference concrete, one can compare the power ratings of the average portable 10” job site table saw to a 10” band saw, which are roughly of the same weight and size. Whereas the contractor table saw is a 15 Amp tool, translating to a bit more than 2 HP, or 1600 W, the 10” band saw is normally powered by a 3 Amp motor, and has only one fifth of the power!

Despite the narrower kerf and thus slightly lower intrinsic power demand of the band saw, this massive difference in usable power results in different cutting speeds. The table saw is capable or ripping a board almost as fast as you can stably feed it, allowing for very high productivity, while the band saw is sure to stall if you attempt similar cutting speeds. Further, running too fast with a band saw lowers the cut accuracy, as the saw blade tends has a tendency of wandering when subjected to a high thrust from the workpiece.

2 Cut geometry

In addition to cutting capacity, the band saw and the table saw have different limitations on the cut geometry.

2.1 Cut line

The most significant difference is that a table saw will cut only straight, while a band saw can make both straight and curved cuts.

This difference is down to the blade type used in the two saws. The blade of a band saw is short, and can easily run a curve inside the wood. The circular table saw blade, on the other hand, is relatively long in the direction of the cut, prohibiting it from making all but the slightest of turns in wood. In fact, attempting to turn is downright dangerous, as it may trigger a hazardous phenomenon called kickback (see ‘Safety’).

2.2 Blind cuts

Sometimes, you may want to make a cut that does not go all the way through the workpiece in the depth direction. Such cuts are called blind cuts, and are needed when making rabbets and dados, for example.

A band saw cannot make blind cuts of any kind. Simply because of how the blade runs, any cut with the band saw must go all the way through. This means that a band saw is not suited for making grooves, rabbets or dados.

The table saw, on the other hand, is the master of blind cuts: the blade reaches into the material only from below, and can be set at any height you want. Depending on your table saw model, you may have to lower the riving knife and perhaps remove the upper dust extraction hood.

There is one way to make rabbets and dados with a band saw: flip the workpiece onto its side, and convert the blind cut into a stopped cut, treated next. However, doing this is tricky, and possible with very short workpieces only.

2.3 Stopped cuts

Yet at other times, you may want to make a cut for some length into the material, and then stop, as in making an inside corner into a piece of plywood. This cut is called a stopped cut, and is the counterpart of the blind cut.

Here, the roles of the two saws are swapped:

A band saw can be very easily used for stopped cuts: all you have to do is to stop feeding the workpiece. The saw will leave the cut end clean and vertical, and allows you to make neat inside corners in your workpieces.

While not completely hopeless, a table saw is quite bad at making stopped cuts. The simple reason behind this is that the cutting front, where the blade teeth are eating the material, is not vertical but inclined. If stop a cut with a table saw, the cut end will not be neat and vertical as with the band saw, but instead an inclined, curved-bottom groove.

This is a serious downside in making inside corners, which is one of the most common reasons you would want to make a stopped cut. To release to corner piece and make an inside corner just with a table saw, you would actually have to cut some distance beyond the corner in both directions, leaving nasty grooves in the preserved part of the work piece.

A common tactic to fix this is to cut almost up to the corner with the table saw, and finish the corner with a jig saw, for example.

There is, again, one way to make inside corners just with the table saw: flip the workpiece to its side, and convert the stopped cut to a blind cut, treated above. Again, doing this may be tricky, and the cut length is limited to about 4”.

2.4 Kerf

The term “kerf” refers to the width of the cut that the saw makes. While rather insignificant in most cuts, kerf is important in cutting rabbets and dados, slits, and in producing veneer by sawing. You will also have to know your kerf and account for it in resawing and in dividing sheets equally into smaller pieces.

The table saw is a circular saw, and has a much wider kerf than a band saw. The exact kerf will depend on the blade that you have installed, but all of the typical fall between .08 and .10’’ (2…2.5 mm).

The wider kerf makes the table saw more wasteful, but the wide kerf also has its benefits. For one, it allows the table saw blade to be stiff and make highly accurate cuts. It will also cut most dados and rabbets with only a few passes.

The band saw, on the other hand, has a very narrow kerf – one of the narrowest of all woodworking saws. A typical kerf for a 10” band saw is around .05” (1.3 mm). This narrower kerf means less wood wasted. The saving may be minor in most applications, but is very significant in sawing wood into veneer, where the the piece cut off is almost as thin as the kerf.

3 Cut quality

The band saw and the table saw also differ in the quality of the cuts they make, understood here as dimensional accuracy and surface finish.

3.1 Dimensional accuracy

Table saws are very accurate: they do not drift or wander, and will cut wood into a very constant width. Indeed, the cutting accuracy of a table saw is determined more by the straightness of the pre-cut side face and your ability to keep this face flush to the saw fence as you feed the workpiece in. Further, many table saws allow you to eliminate these largest error sources by using a sliding table, taking your cuts to an accuracy which will suffice for any conceivable woodworking project.

The excellent accuracy provided by the table saw is very useful in many woodworking projects. For example, it allows you to forgo a jointer when laminating.

Band saws, on the other hand, are only moderately accurate, and not the optimal choice for making very straight cuts. The main reason behind this is the thin and flexible blade, which, despite a high pretension, is sensitive to side forces and prone to drifting. Any drift in the blade during the cut will result in a crooked cut.

The band saw blade drift can be caused by a number of reasons, such as a bad blade set, asymmetric wear or fouling; it can even be caused just by an oblique grain in the workpiece. While the drift can often be practically eliminated with adjustment, this may require painstaking efforts, and the drift will often return as the blade wears.

A band saw is accurate enough for most work, but the presence of some blade drift means that it is not well suited for precise miters or joints. Further, exposed band-sawn surfaces may require planing or sanding to hide waviness and blade marks.

3.2 Surface finish

In addition to being accurate, table saws also leave a very good surface finish on the cut faces. Thanks to the high cutting velocities and the sharpness and precision of the hard metal teeth on the blade, the cutting process is clean and consistent, and the cut surfaces smooth and free of tears or burring.

The good surface finish means that for many applications, a table-sawn surface is ready as it is – it will not require planing or sanding before finishing. It also allows for very clean joints, miters and other details without additional processing, provided that tearout is prevented.

A band saw, on the other hand, leaves a somewhat rougher finish on the cut surface. There are two principal reasons for the lower surface quality:

- Lower tooth accuracy: The band saw blade is much simpler than a table saw blade: the teeth have been cut and ground into the band itself, and then given a set by bending them outwards. The dimensional accuracy of such teeth is not on par with those in a table saw blade, and they lack the side cutting faces.

- Blade vibration: the long and slender band is prone to vibrating in the unsupported length where the cutting happens. While this vibration can be minimized with proper machine balancing, it still troubles all band saws to an extent.

Because of the roughness, a band-sawn surface is generally not ready for finishing as such, but must instead be planed or sanded prior to application of varnishes or paints.

4 Practical considerations

Apart from their different cutting capabilities, band saws and table saws differ in many practical aspects such as user safety, noise level, flexibility with different materials, dust extraction, size and cost.

4.1 Safety

All saws are hazardous: they will cut your hand just as they cut the workpiece.

Yet all saws are not equally hazardous. The table saw is undoubtedly one of the most dangerous saws there are. It is powerful, fast and has a blade with teeth exposed in three directions. Many a woodworker has lost fingers, a hand or even their life when operating a table saw.

In addition to the usual cutting danger, the table is also susceptible to a instability called kickback. Kickback is a chain reaction, which can be triggered when the blade teeth bite into wood already at the back of the blade, and will send the workpiece hurling towards the saw operator.

A band saw, by contrast, is only moderately dangerous as a saw. While the band saw will also cut your hand and has the potential to cause serious injury, it is clearly safer than a table saw. The main reasons for this are:

- A relatively protected blade: the blade is exposed only from the front and for a short distance. This means that any accidental feeding of hand towards the blade from the back or the sides is less likely to lead to a serious injury.

- Stabler cut: As the blade moves into the table, the sawing force is directed downwards and presses the workpiece downwards, helping to keep it steady.

These risk profiles may often be slightly evened by psychology, though: whereas the loud whoosh, scary looks and even scarier reputation of the table saw makes the average operator cautious and reduces the risk of an accident, one of the main risk in operating a band saw is false sense of safety brought about by the stability and low noise levels. Put in other words: the table saw is dangerous, but also feels like that, while the band saw is a silent killer.

Last, it should be noted that all saws are relatively safe when operated properly, and very dangerous when operated improperly – proper technique counts more than the saw type.

4.2 Noise

Table saws are very loud due to the high blade velocity and motor power. A typical quoted sound power level for a contractor table saw is 100–110 dB(A).

Band saws, on the other hand, are relatively quiet powered saws. This is thanks to the low-speed induction motor and low blade speeds. A well-balanced band saw generates only little mechanical noise while free-running, and most of the noise in operation comes from the cutting process itself. Although exact decibel numbers for band saws are hard to come by, the sound level is noticeably lower than with a table saw.

Since both saw types clearly require hearing protection for the operator, the difference in noise level is more relevant for adjacent spaces, where the louder table saw may cause more annoyance than the quieter band saw.

4.3 Dust extraction

Band saws are typically very clean saws as far as dust emissions are considered: the cut is concealed, and the blade carries most of the dust and shavings with it into the lower wheel case. When a dust extractor is coupled to the port in the wheelcase, its added suction at the table opening effectively prevents any dust from escaping.

Table saws, by contrast, are usually much messier, and even the best dust extraction efforts are only partially successful. While the blade does carry most of the dust into the blade case, this case is much more open than the wheel case of the band saw, and the dust extractor, which can be coupled to the blade case, must battle the strong circulating air currents induced by the fast blade. Some models include an extraction hood on top of the blade, which reduces the amount of dust escaping into the air.

4.4 Multi-material

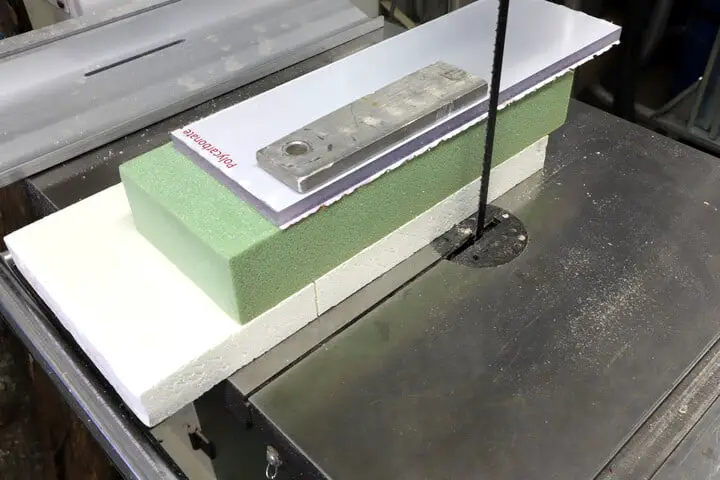

Both the band saw and the table saw can cut a wide variety of materials: wood, wood products, plastics, foams and soft non-ferrous metals like aluminum, copper, and brass.

However, the two saws differ in the ease at which these different materials can be cut. The band saw is quite flexible, and can cut workpieces all the mentioned materials easily and safely.

The table saw, on the other hand, can cut most of the same materials, but requires more caution in doing so. The fast blade may melt or burn plastics if you use too slow feed rates, for example, or throw metal workpieces around if the piece guiding is not stiff enough.

If you often must use the same saw for very different materials, the band saw clearly has an advantage over the table saw.

4.5 Size

Band saws and table saws are both large saws, and will take up significant space in your workshop. Nevertheless, they do differ in shape and size in a way that may affect your choice of saw.

Table saws are wide but relatively flat: a typical contractor model measures 28” x 28”, but is only 13” high. They also vary relatively little in size, The convenient form factor allows you to put the table saw on a mobile platform and push it under a table when not in use. Some larger models intended for shop use are available, though, and often come with an integrated stand.

Band saws, on the other hand, come in a range of sizes, but are always relatively wide and tall. This form factor combined to their weight makes even the smallest 9” models difficult to stow away. Band saws are usually intended to stay in one place: the smaller models on the bench top, and the larger ones on a stand on the floor.

4.6 Footprint

In addition to the physical size, saws require some working space around them. The saw plan area and the working space together form the effective footprint of the saw in your shop.

In practice, band saws and table saws have the same effective footprint. The reason for this is that both band saws and table saws are stationary saws, which means that the workpiece, not the saw, moves during the cut.

To see this better, consider the extent of the workpiece motion during the cut. Both with the band saw and the table saw, you will have to reserve

- one workpiece length in front of the saw,

- one workpiece length behind the saw, and

- almost one workpiece width to one side of the blade, depending a bit on where the cut line is

If your workpiece of any substantial size, it is the workpiece dimensions, not the saw dimensions, that define the amount of working space you need.

4.7 Cost

Table saws and band saws come with different price profiles.

Band saws are available at very wide range of prices, explained mainly by the size. The smallest bench top 9” models are very affordable, starting at only a little over $100. The price rises quickly with size, however, as the 10” models average around $350, the very popular 14” size will usually cost more than $1000, and 17” and larger models are several thousands or dollars.

The prices of table saws are much flatter, just as the sizes: the job site or contractor sizes 8 1/4” and 10” come at about $350 and $450, respectively, with battery-powered versions and major brands commanding a small premium. Shop versions with wide cast iron tables exist, and will set you back several thousand dollars, though, but are somewhat rarer purchases.

Although the 9” band saws seem like the best bargain here, it should be noted that most users find their power and accuracy lacking in many application. Instead, the most bang for the buck is arguably delivered by the popular, high sales volume job site table saws.

Application profiles

We have now gone through the differences between band saws and table saws in detail. But how do they compare in typical application fields? And which one should you get? Let us now give more definite answers based on the information presented above.

1 Construction

A table saw is clearly better than a band saw for most work at a job site, where most cuts are straight, most workpieces large, and productivity is key – the table saw is made for just this kind of work.

Table saw models are also more portable than band saws, which is a big advantage in job site use. Table saws are lighter and smaller, and often equipped with carrying handles for easy lifting in and out of the van.

2 Resizing lumber

Table saws are usually better than band saws for resizing lumber: they are faster, more precise, and leaves a smoother cut surface. The cut height is usually limited to about 4’’, though, so for the thickest resawing, the band saw is your only option.

3 Sheet goods

A table saw is preferable to a band saw for most work with sheet goods. The reason for this is the small cut width of the band saw, which is particularly restricting when working with sheet goods.

However, if you need curved cuts into sheet goods, the band saw is your only choice. In this case, you have to make sure the workpiece will fit between the blade and the frame.

4 Remodeling

Sawing in remodeling is mostly cutting sheet goods and resizing lumber, so table saw is better here too!

5 Furniture-making

Band saw and table saw both have their uses in furniture-making. However, the band saw is clearly more versatile as it allows cutting both the straight and the curved shapes, whereas the table saw will cut only straight.

In general, the more curved your designs are, the more you are going to need a band saw. Many modern and simple designs need only straight cuts, and can be made more efficiently with a table saw.

6 Cabinetry

A table saw is better than a band saw for cabinetry, since the cuts involved are almost exclusively straight and should be done with high precision. The table saw will make these cuts faster, more precise, and with a smoother finish.

7 Decor

A band saw is better than a table saw for decorative wood items. These items usually involve curved shapes, which a table saw is unable to cut.

Further, decorative items are often produced in low numbers, relatively small and finished by sanding, so the lower productivity and rougher cut of the band saw are not an issue.

8 Prototyping

A band saw is usually better than a table saw for prototyping and product development work. Such work often involves a wide range of materials – woods, plastics, foams, metals – and small workpieces. While these can be cut with both saws, cutting them stably and safely is often a lot easier with the band saw.

Other saws

But how about all of the other saw types – band saws and table saws are hardly the only saw types out there?

When choosing between a table and a band saw, it is advisable to consider how either of these saws would work together with other saws that you may have. Indeed, many affordable and compact saw types such as handheld circular saws or jig saws can be combined with either the band saw or the table saw to cover a wide range of use cases. These combinations can come in very handy, as they may allow you to dispense with either or both the large saws.

For example, if you are a builder who also occasionally enjoys finer and decorative woodworking, you can replace the band saw with a jig saw for curved cuts, and use your table saw when you go straight.

On the other hand, if you enjoy making traditional furniture, but also do occasional remodeling, you may skip the table saw and complement your band saw with handheld circular saw instead, saving you some money and a lot of space.

Conclusion

As we saw, band saws and table saws have many things in common some overlap in applications, but have some distinct strengths.

In general, you should probably prefer the band saw for fine woodworking; the rougher your work and the simpler or more modern your design, the more you should prefer the table saw.

Prefer the band saw for traditional and fine woodworking, and the table saw for construction, remodeling and modern cabinetry.

Whether you will get away with just one of these saws depends on your work profile. If you work is very varied and budget and space not very limiting, you should probably get both a table saw and a band saw.

If, on the other hand, you would need either of the saws only occasionally, you might want to consider if you could replace it with a smaller handheld tool.