In the previous posts, we went through AGM battery charging fundamentals: charging stages, voltages, and rates, currents and times. In this article, we are going to focus on chargers: what kind of chargers you should use for AGM batteries, and what are the specs to look for.

In a nutshell, AGM batteries are best charged with a three- or four-stage smart charger with a dedicated AGM mode. These chargers have voltage levels and stage timing optimized for AGM batteries, providing an efficient charge and longest battery life. Most smart chargers and battery maintainers for other lead-acid battery types can also be used, but more monitoring from the user.

Below, we will discuss the applicable AGM charger types in more detail. I will tell you how to choose charger voltage and amperage, and give some guidelines for charging RV and boat AGM house batteries. In the end, we go through some of the most common questions on AGM chargers.

Lead-acid charger types

There are at least four types of lead-acid battery chargers which could be used for AGM-type batteries too. The charger types, with a short description, are:

- Conventional: bulk–absorption cycle, constant-current–constant-voltage (CCCV), analog electronics, regulation varies

- Smart 3-stage: bulk–absorption–float cycle, microprocessor control

- Smart 4-stage: bulk–absorption–float–storage cycle, microprocessor control

- Maintainer: float or storage cycle, low current; may allow slow primary charging.

Next, we see how well each of these work for AGM batteries, starting from the best; below, you can also find a summary table.

| Charger type | AGM compatibility | Notes |

|---|---|---|

| Analog lead-acid | no | overcharging risk |

| Smart 3- or 4-stage, AGM mode | yes | optimal |

| Smart 3- or 4-stage, no AGM mode | yes | use lead-acid mode |

| Battery maintainer | most yes | use AGM mode, temp. comp. |

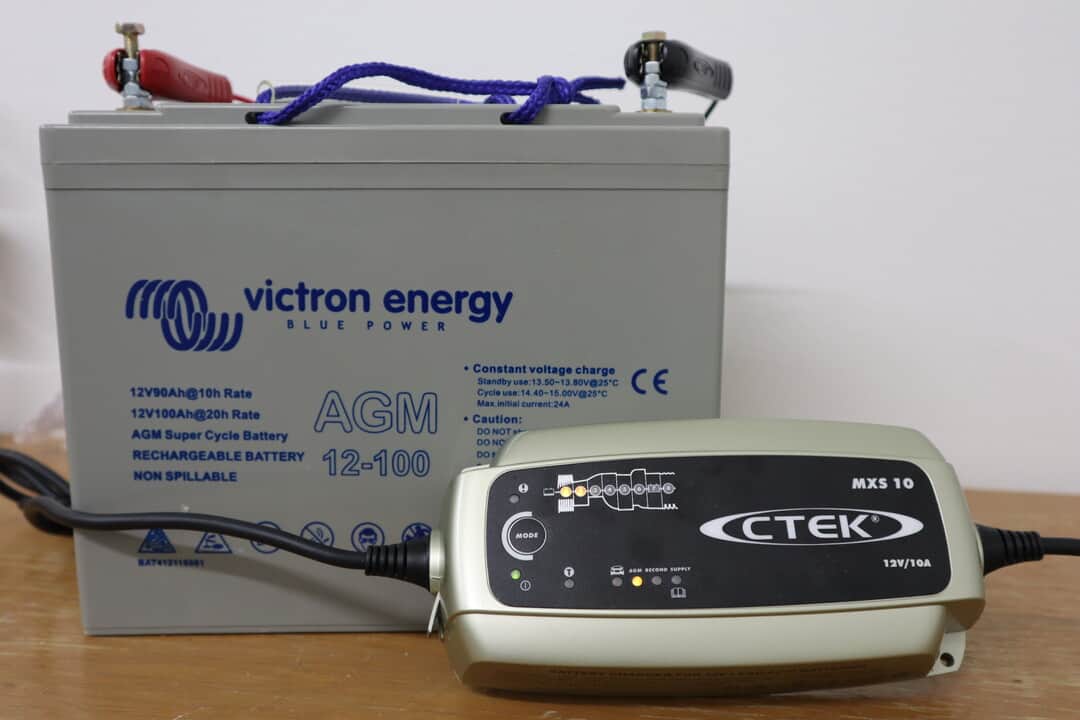

Smart charger with AGM mode (Best)

AGM batteries are best charged using a smart charger with a dedicated mode for AGM batteries.

Smart chargers are essentially chargers with intelligent control electronics. These chargers can monitor and control both charging current and voltage and switch the charging stages optimally. Smart chargers typically employ either a three- or a four-stage charging cycle.

AGM mode: A dedicated AGM mode in the charger is very useful in that it sets the absorption and float voltages and stage timing so that they are optimal for AGMs. This makes the charging process as efficient as possible and minimizes the risk of over- or undercharging.

3-stage vs. 4-stage: Both three- and four-stage smart chargers are OK for AGM batteries. The difference lies in the maintenance part of the charging cycle: four-stage chargers have a dedicated long-term storage mode, claimed to be better for battery health than months of float.

Temperature compensation: Many smart chargers can adjust the charging voltages based on temperature. This is a very useful feature for charging at high currents or in variable conditions. The temperature is measured with an external thermistor on the battery or, with very low currents, inside the charger; some models may just allow manual temperature input by the user.

How to identify a smart charger: Smart chargers have multiple mode buttons, indicator leds, and sometimes a display. They may also have “smart” in the product name. Most battery chargers in sale in 2021 are smart, and have descriptions like “3-stage” or “3-phase”, “IUoU”, “automatic”. Conventional chargers are older models, and usually have an analog current gauge and rocker switches for voltage and current selection.

| Smart charger, AGM mode Pros & Cons: |

|---|

| + fast and efficient charging + cycle and maintenance charge + automatic float – you may have to buy one |

Smart charger without AGM mode (OK)

Some smart chargers do not have a dedicated AGM mode. While not quite optimal, the standard flooded lead-acid mode of these chargers can still be used for AGM batteries.

The main drawbacks of using the flooded lead-acid mode for an AGM battery are possibly non-optimal absorption and float voltages, and sometimes absorption timing. While recommendations vary from source to source and between manufacturers, AGM batteries on average have higher recommended absorption and float voltages than flooded lead-acid batteries. The flooded lead-acid mode is likely to have voltages a bit on the low side for AGMs, and its use carries a slight risk of undercharging.

| Smart charger, no AGM mode Pros & Cons: |

|---|

| + safe charging (if for lead-acid!) + cycle and maintenance charge + automatic float – voltages not optimized for AGM |

Battery maintainer (OK for storage)

Battery maintainers are low-power chargers intended for maintenance charging during battery storage. These chargers have outputs of a few amps at maximum and are typically small, dust- and waterproof and affordable.

Battery maintainers are excellent for charging AGM batteries in storage. Practically all new battery maintainers are smart, i.e. have intelligent battery state detection and stage switching, and most are compatible with AGM batteries. Keeping your AGM battery hooked up to a battery maintainer through the storage season ensures the battery stays in optimal condition and relieves you from having to manually charge it every 6-12 months.

Most battery maintainers can also recharge small AGM batteries. Although intended for storage charging, the majority of battery maintainers actually have the full bulk–absortion–float charging cycle programmed in. This allows charging drained AGM batteries like just like regular chargers, only slower.

Temperature compensation: If your AGM battery will undergo large temperature swings during storage, be sure to check the battery maintainer features temperature compensation. This would be the case for batteries in vehicles and boats stored outdoors or in unheated storage. AGM batteries are more sensitive to the charging voltage than flooded lead-acid, and the fixed voltages optimized for +25°C or +77°F will lead to undercharging in cold and overcharging in hot environments.

| Battery maintainer Pros & Cons: |

|---|

| + smart + maintenance charge + cycle charge for small AGM – slow – voltages not optimized for AGM |

Conventional charger (not good)

Conventional or regular flooded lead-acid battery chargers can charge AGM batteries, but require constant monitoring and are not recommended for AGMs.

The conventional/regular/normal lead-acid battery chargers sold in the past decades are essentially current-limited voltage sources without much control electronics. They start the charging with a current limit and then top out to a voltage limit when the battery gets close to full charge.

This constant-current–constant-voltage (CCCV) cycle is actually quite similar to the bulk and absorption stages of more advanced chargers, and would in principle work for cycle charging AGM batteries. There are two major drawbacks in AGM battery charging.

The first issue is poor absorption voltage regulation. In my personal experience, regular chargers may top out anywhere between 14.2V and 15.2V, and I have heard some creeping up to even 16V or 17V. AGM batteries are much pickier on the absorption voltage than flooded lead-acid units, and may suffer damage from over- or undercharging with a regular charger.

The second issue is that conventional chargers have no float stage. Whereas smart chargers limit the absorption time and automatically step down to float to prevent overcharging, to conventional chargers keep the battery at the absorption voltage indefinitely. This risks overcharging the battery, to which AGM-type units are particularly sensitive.

Due to these problems, I do not recommend charging AGM batteries with conventional chargers: there is a major risk this will damage your AGM unit.

AGM Charger sizing

Amperage is one of the main charger specs you should check when picking a charger for your AGM battery. The charger maximum current output will set the upper limit to how fast you can charge your battery.

As a rule of thumb, look for a charger that has enough output amps to produce a 0.1C charge rate for your battery. This is the standard AGM bulk charge rate, and fast enough to fill the battery overnight. How many amps this takes depends on the battery size: for the 0.1C charge current in amps [A], divide the battery amp-hours [Ah] by 10.

The table below lists the 0.1C rate charging currents for some common AGM battery sizes, and includes also the current for the 0.2C fast charge rate. For more on rates and currents, see the previous part of this series.

| Battery capacity | Charger current, 0.1C rate | Charger current, 0.2C rate | Typical application |

|---|---|---|---|

| 15Ah | 1.5A | 3A | motorcycle |

| 60Ah | 6A | 12A | car |

| 100Ah | 10A | 20A | truck |

| 200Ah | 20A | 40A | solar systems, boats |

AGM Charger voltages

6V/12V

The most popular AGM charger voltage is switchable 6V/12V. This matches the most common single AGM battery voltages of 6V and 12V. The 6V/12V chargers therefore allow you to charge most AGM units you will find in boats, vehicles and backup power systems.

Smaller vehicles and systems will typically have a single 6V or 12V AGM unit or many of these in parallel – here the 6V/12V chargers are directly compatible.

Larger vehicles and power systems may operate on AGM battery banks with 24V or higher nominal voltage. The 6V/12V chargers can charge these banks, but only after you take the bank apart to either 6V or 12V units.

12V/24V

The second most popular charger voltage combination is 12V/24V. These chargers will allow you to charge AGM units, whether single or bank, with nominal voltages of 12V or 24V without the need to disconnect batteries from each other.

The 12V/24V voltage combination is quite versatile as it covers most boat and vehicle power systems out of the box. The biggest drawback of 12V/24V chargers is that they cannot charge individual 6V AGM batteries, which are a common building block in larger battery packs. Individual charging is sometimes necessary in service or with variable condition units.

24V, 36V, 48V

Higher-voltage chargers for large AGM battery banks are also available for special applications such as solar power systems, golf carts and mobile equipment. These chargers are usually large-power and expensive and have limited use outside charging the battery pack they are intended to serve.

AGM chargers for special applications

Golf cart

Golf carts typically use AGM battery packs consisting of multiple 6V, 8V or 12V units in a series connection. The total output voltage of the battery packs is commonly 36V, 48V or 72V and the capacity of both the pack and the units is around 200Ah.

Golf cart batteries are almost always charged as a pack. Therefore they take a special golf cart battery charger with a high 36V, 48V or 72V output voltage.

The charger amperage should be matched with the battery pack capacity and cart use cycle. For carts in daily duty, the charger should get close to a 0.1C charging rate; this rate is required to get a 75% discharged AGM pack full in 12h, i.e. overnight. (For more info on charging times, see previous part.)

RV

The AGM house batteries on RV’s are charged from a line outlet when parked, from the alternator when driving, or from solar panels (parked or on the road). While solar charging is best done by a dedicated solar charge controller, line charging goes with general-purpose AGM chargers.

Most RV’s employ either a 12V or 24V power system (12V more common), and are best served by an AGM charger with a matched voltage of either 12V or 24V.

The battery capacities range between 100Ah and 400Ah, and should in typical RV use be charged full overnight (12h). This requires a 0.1C charge rate, which takes a charger with 10A to 40A output capacity, scaling with the battery pack size. For more info, check the previous part.

Boat

Similar to RV’s, cruise and sail boat house AGM battery packs are 12V or 24V nominal voltage, but typically have higher capacities between 200Ah and 600Ah.

As with RV’s, boat house batteries are charged from engine alternator, solar power or shore power. Alternator and solar need charge controllers of their own, but shore charging can be done using general-purpose AGM chargers.

A boat AGM battery shore charger should match the 12V or 24V pack voltage, and should ideally have enough output capacity for a 0.1C charge rate. This rate ensures that a 75% drained pack is charged full during an overnight (12h) shore connection.

With 200Ah to 600Ah of battery capacity, the 0.1C rate requires largish charger current outputs of 20A to 60A. Shallower discharge or longer shore stays allow a full charge also with a smaller charger.

AGM Charger Q & A

Can you use a regular charger for AGM batteries?

This depends on what is meant by “regular”:

- Most microprosessor-controlled 3- or 4-stage smart chargers for flooded/wet lead-acid batteries work with AGM batteries, although the voltages may not be exactly optimal

- Conventional analog, non-smart chargers do not work well with AGM batteries.

For more info, see above.

Can you charge an AGM battery with a power supply?

An AGM battery can technically be charged with a power supply, but safe use requires constant monitoring and a detailed understanding of both AGM charging and power supply operation, and is not recommended.

As such, a power supply lacks the correct staging, current limits, voltage levels and safety features built into smart battery chargers. Applying these would be up to the user, and failure could permanently damage the battery and risks injury to user and fire.

Can you use a Li-ion or LiPo charger for AGM batteries?

Charging AGM batteries with a charger intended for lithium-based batteries is not recommended.

While the charging profiles for the two battery types are superficially similar, all of the details are different: stage durations, voltage levels, currents, etc. The biggest qualitative difference is that lithium-based battery charging profile has no steady float stage. A lithium charger will probably charge an AGM battery at least partially, but is also likely to damage it.

Can you use a gel charger for AGM?

A charger intended for gel-type lead acid batteries can be used for charging AGM batteries, although it is not an optimal choice.

Gel and AGM batteries are usually charged with the same 3-stage bulk–absorption–float cycle, but enjoy slightly different voltage levels. A gel charger typically has absorption and float voltages 200 mV to 400 mV lower than optimal for AGM batteries, and may leave an AGM battery slightly undercharged. While acceptable in occasional use, routine undercharging an AGM battery with a gel charger leads to premature capacity fade and is not recommended.

Do you need a special charger for AGM?

No special charger is needed for AGM batteries, as most general-purpose smart chargers for lead-acid batteries have an AGM mode, or are otherwise compatible. However, use of older analog chargers is not recommended. For more details, see above.

What size charger for an AGM battery?

The best charger size for an AGM battery depends on the battery capacity in amp-hours (Ah) and a bit on how fast you want the battery charged.

The standard recommended charging rate for an AGM battery is 0.1C, which requires charger amps around 1/10th of the battery capacity in amp-hours (Ah): 5A for 50Ah, 10A for 100Ah, etc. This rate will charge a deep discharged (75% to 90% DoD) AGM battery to 100% full in 12 to 15 hours.

For a charger amperage overview, see section above; for more on charging rates and currents, see previous part.