The Alaskan Mill is a portable chainsaw milling attachment manufactured by the US company Granberg International. In the recent years, Granberg has come out with the fourth version of the mill – the Alaskan MKIV. Having owned only an ultralight Swedish chainsaw milling attachment, I decided to give the more traditional Alaskan Mill a try.

In this article, I will share my first impressions of the Alaskan Mill MKIV with you. In short, the Alaskan Mill MKIV is a well-built and easy-to-use chainsaw milling attachment compatible with all practically chainsaws. The Alaskan Mill offers good accuracy and great cutting capacities up to 84″, and the MKIV version has seen improvements in the end brackets. Starting at $240, the Alaskan Mill MKIV is not cheap, but provides decent value for the money.

Below, we are going to look at ease of assembly and use, build quality, accuracy, and saw compatibility. Finally, I will also share my view on how the Alaskan Mill relates to the competition, and whether it is good value for your money.

| Alaskan Mill MKIV Review summary: | Grade: |

|---|---|

| Ease of assembly: | +++++ |

| Build quality: | +++++ |

| Ease of use: | +++++ |

| Accuracy: | +++++ |

| Saw compatibility: | +++++ |

| Value for money: | +++++ |

| Overall: | +++++ |

| What I liked: + easy to use + reliably accurate + fits all chainsaws | What I did not like: – galvanized parts – no quick-locks |

Ease of assembly: +++++

The Alaskan Mill is delivered unassembled and before using it, you have to put it together.

Fortunately, the Alaskan Mill comes with good instructions and the assembly is easy: I got the rig unpacked and together in about 20 minutes.

Assembled, the Alaskan Mill has both length and height to it. Luckily the bar grips slide off the rig easily, allowing you to quickly pack it flat for transportation.

Quick release fasteners are something I would have liked to see in place of the hex nuts and Allen screw connections. These would have made both the initial assembly and all setups before sawing quicker.

I give the Alaskan mill 3/5 stars for ease of assembly.

| Grade for ease of assembly: +++++ |

|---|

| Pros: + clear instructions + reasonable assembly time Cons: – no quick releases |

Build quality: +++++

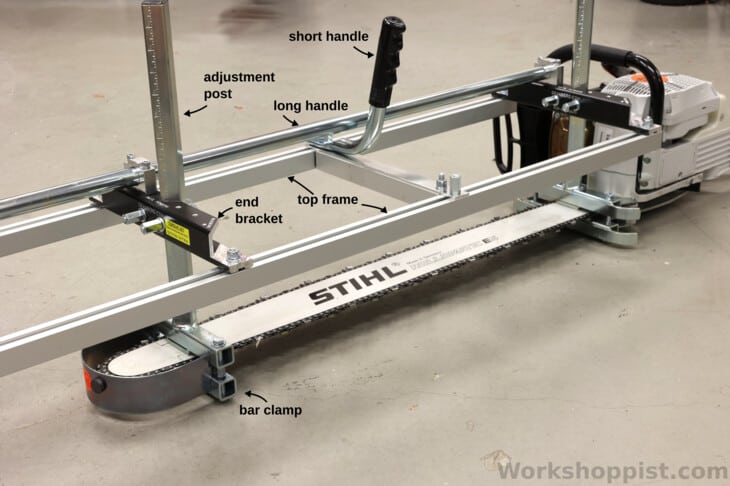

The Granberg Alaskan Mill MKIV appears well-built and leaves an impression of high quality. I have a lot to say here, and divide my comments to five subsections: frame, end brackets, adjustment posts, handles, and connecting hardware; see image below for the part names.

Frame

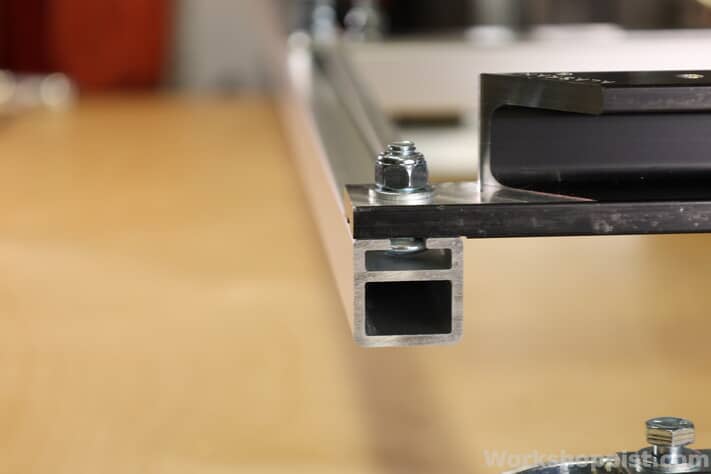

The frame of the Alaskan Mill is constructed from 1-1/8” extruded aluminum square tubing. The tubing is thick-walled (7/64”, 2.85 mm) and perfectly straight; Granberg describes the material as ”aircraft aluminum”, but does not specify the alloy. I suspect it is either the high-strength 7075 or the more common 6061.

The frame construction is solid and above average. Many of the affordable alternatives you can find in online hardware stores feature similar rails, but based on the product images, the wall thickness of the aluminum tubing they employ seems a bit less than that of the Alaskan Mill.

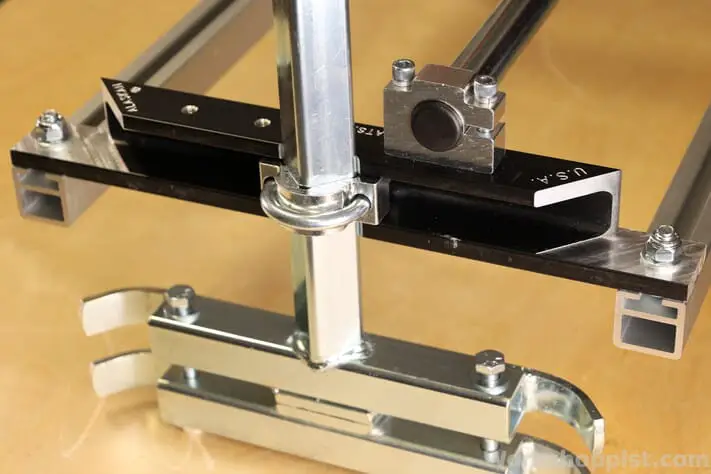

End brackets

The end brackets are one of the updated features in the Alaskan Mill. The MKIV brackets are CNC machined aluminum billet, claimed to be easier to use and more accurate than MKIII brackets and “virtually unbreakable”.

The brackets indeed feel reassuringly solid: thick walls (1/4”…11/32”), milled contact surfaces and a black matte finish on the rest of the bracket. These are my favorite part in the entire Mill, and I have no reason to doubt Granberg’s claims here.

The machined end brackets are definitely an upgrade to the cast brackets seen in the previous version of the Alaskan Mill, as well as in most of the affordable alternatives. The U-shaped cross section is stiffer, and the machining guarantees that the contact surfaces of the bracket are flat and precise.

Adjustment posts

Binding to the end brackets of the Alaskan Mill are adjustment posts used to set the depth of cut. These posts consist of a graduated vertical square tube and a two-piece bar clamp at the lower end.

The adjustment post assemblies are galvanized steel throughout and feel solid. The welds in the assemblies are not the prettiest I have seen, but OK enough. I would have liked to see these assemblies made of aluminum for greater corrosion resistance and weight savings.

A fine detail on the posts: the scale is stamped, not printed. This ensures that it is not going to wear off or be dissolved by chain oil or gasoline – see photo below.

Handles

Something I am less happy about is the use of galvanized steel tube for the handles and some of the small hardware parts in the Alaskan Mill.

While the galvanization will give these parts some corrosion resistance, they will inevitably rust over time. They are in contact at many points with aluminum parts, and the corrosion rate may be increased by the material pair.

Making the handles and hardware parts from aluminum just as the frame would have avoided corrosion issues and brought some weight savings.

Connecting hardware

The Alaskan Mill comes with a small bag of screws, nuts and washers. This connecting hardware is OK but zinc-plated instead of stainless. While I would not worry of rust compromising the joint strength, I am slightly worried of the joints seizing and becoming more difficult to use over time.

| Grade for Build quality: +++++ |

|---|

| Pros: + machined end brackets + aluminum frame Cons: – galvanized steel handles – galvanized hardware |

Ease of use: +++++

Setup

Using the Granberg Alaskan Mill MKIV is very simple and much fun.

After initial assembly, each use of the Alaskan Mill starts with setting up the mill: insert the adjustment posts to the frame, clamp the saw bar into the adjustment posts, lock the frame and set the depth of cut.

This setup took me around two minutes after some practice. The bar mounting mechanism is genius: the clamps grip tight on any bar without drilling.

First cut

Like many other chainsaw mills, the first cut into each log requires a guide and is the most difficult one.

Any straight plane can serve as a first cut guide. A pair of 2×4’s or an aluminum ladder are popular choices, but Granberg also sells a rail system for the purpose (EZ rail).

The first cut guide setup is straightforward, but takes some attention: you need to make sure the guide is straight and free of twist. A level is an indispensable tool in this.

Following cuts

After a decent first cut, sawing with the Alaskan Mill is smooth sailing. The mill rests on the sawn surface and all you have to do is keep the saw RPM constant and apply a steady push.

I was actually surprised of how stable the mill runs through the log. Gravity kept it level against the top surface and the chain pulled it against the log – all I did is push.

Some extra care is required when starting and finishing. You must also remember to stop and drop in a few wedges to support the cut every now and then, and resist the temptation to seesaw. But otherwise very simple!

| Grade for Ease of use: +++++ |

|---|

| Pros: + saw attachment is easy + very simple mill operation Cons: – setup could be faster |

Accuracy: +++++

Lumber made with the Alaskan Mill MKIV is as accurate as your first cut guide.

Dimensional accuracy: I found the Granberg Alaskan Mill MKIV to run and cut very consistently, so that the straightness of the boards is up to the first cut guide you use.

With a good guide – a straight ladder supported every 8 ft. and ends leveled – you will get very straight lumber. If your guide is sloppy or crooked, so will your lumber.

Surface roughness: The Alaskan Mill produces as fine a surface as you can expect from a chainsaw. This is thanks to the rigid bar support at both ends which eliminates vibrations. I saw none of the washboard pattern I have had with the Logosol Timberjig.

With the Alaskan Mill, the surface finish more up to the chain and your working technique. For best results, use a ripping chain and a steady forward push (no seesaw).

| Grade for Accuracy: +++++ |

|---|

| Pros: + consistent cut thickness Cons: – first cut precision up to your guide |

Saw compatibility: +++++

Saw compatibility is one of the strengths of the Alaskan Mill: the Mill can be used almost any chain saw and guide bar combination.

This is thanks to the clever bar attachment system. The Alaskan Mill attaches only to the guide bar using the two clamps at the end of the adjustment posts: no need for drilling holes or having any certain bar stud spacing.

Make sure that your guide bar is long enough for the log that you are planning to mill. Note that you will also have to reserve some extra length for the clamps at the tip and the powerhead.

Second, check that your bar (with chain) is not too wide to fit into the clamps. Based on my measurements, the maximum bar width seems to be a little over 4”, which would cover the majority of saw bars.

| Grade for Saw compatibility: +++++ |

|---|

| Pros: + fits almost any saw + no modifications needed to saw or bar Cons: – does not fit very wide bars |

Value for money: +++++

The Granberg Alaskan Mill MKIV is not the cheapest chainsaw mill on the market. At between $240 and $410 depending on the length, the mill is on the expensive side for a chainsaw milling attachment. Affordable alternatives with the same basic operational principle are available for around $100 (see notes in next section).

On the other hand, the Granberg Alaskan Mill is only a fraction of the cost of framed chainsaw mills with a log bed and external saw guides. Such systems as offered by the US&Canada-based Norwood or the Swedish Logosol will cost you $1000 or more.

In my view, the Alaskan Mill certainly could be cheaper, but offers quite a lot of milling performance for a few hundred dollars. I think the value proposition neither excellent or bad, but just OK. I give it 3/5 for value for money.

| Grade for Value for money: +++++ |

|---|

| Pros: + Affordable compared to framed chainsaw mills Cons: – Expensive for a chainsaw milling attachment |

Against competition

Alaskan MKIV vs. Budget mills: The Granberg Alaskan Mill competes against a large number of more affordable (~$100) chainsaw mills of the same basic construction, many of which appear very similar to the older Alaskan Mill MK-III. I have no experience with the budget mills, but they obviously lack the milled end brackets, and I would expect them to cut corners elsewhere too.

Alaskan MKIV vs. MKIII: The new MKIV has the updated end brackets, which should be easier to adjust, stronger and stiffer.

Alaskan Mill vs. Logosol Timberjig: Compared to the ultra-light Timberjig, the Alaskan MKIV is bigger, heavier and a bit pricier. However, the Alaskan is easier to use in my experience and has a much higher cutting capacity. Timberjig is great for making full-edged lumber from small logs, but the Alaskan MKIV is better for everything else.

Overall: +++++

I give the Granberg Alaskan MK-IV a 4/5 star overall rating.

The Alaskan Mill is undoubtedly one of the best chainsaw milling attachments, and counts for many as the chainsaw mill. The MKIV version features an updated end bracket, and although the improvements are not major, they show that Granberg is still putting effort into the product development.

The Alaskan Mill is undoubtedly one of the best chainsaw milling attachments, and counts for many as the chainsaw mill.

Breaking the verdict down to areas, the build quality of the Alaskan Mill MKIV is decent, and excellent for the end brackets. The mill is relatively easy to assemble and packs almost flat when the handles are taken off. Thanks to the simple operating principle, using the mill is straigthforward, and the cuts are dimensionally accurate and consistent. Special thanks are due for wide, almost universal saw compatibility.

Although the Alaskan Mill is on the expensive side of simple chainsaw milling attachments, I would say it is decent value for your money.

Alaskan Mill MKIV Quick Specs

The Granberg Alaskan MKIV specifications can be found at Granberg’s and many supplier websites. For quick reference, I assembled the key specs to the table below.

| Granberg Alaskan Mill MKIV Specifications: | |

|---|---|

| Size | 12½” x 24”… 84” (length optional) |

| Weight | 18…27 lb. (shipping) |

| Price | $241 … $412 |

| Compatible saws | all, > 50 cc recommended |

| Max bar height | ~ 4” (my estimate) |

| Capacity, thickness | ½” … 13” (for all models) |

| Capacity, width | 20” … 78” (depends on model) |

A few notes on the specs:

- The Alaskan Mill comes in different length versions. The mill length is length of the top rails and the long handle, and the overall length at the same time. The max cut width is around 4” less than the specified mill length.

- The weight is the shipping weight of the product; for my 48” version, the assembled mill weighed around 18.5 lb., which is 2.5 lb less than the shipping weight specified by Granberg.

- The max bar height is not specified in the product information, but my own estimate instead.