The reciprocating saw and the angle grinder are two of the most popular power tools for cutting metal and other hard materials. Compared to a plain hack saw or other hand saws, either tool will take your productivity to a completely other level.

Conventionally, the reciprocating saw and the angle grinder have had a slightly different application profile: the reciprocating was used mostly for soft workpieces from wood up to mild steel, and the angle grinder for harder materials. For the whole gamut, most shops have had both tools.

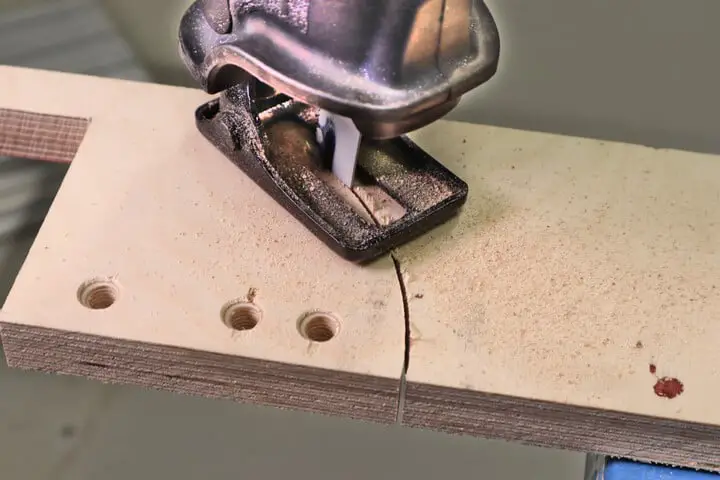

With the introduction of an ever wider selection of different blades and discs for the two tools, you may wonder how do the reciprocating saw and the angle grinder compare today? Equipped with the latest carbide and diamond blades, can the reciprocating saw compete with the grinder in cutting steel? Which one is more versatile? Which should you get first, and can you make do with only one or the other?

This article will put the two cutters head-to-head and give you an overview of their capabilities. In short, a reciprocating saw can cut any material given the right blade, has a higher cutting capacity and produces less noise, sparks and dust, making it the more versatile general-purpose cutter. The angle grinder is better for metalworking in general, as it can cut practically all hard materials and also grind, sand and polish.

In this article, we will go through the differences between a reciprocating saw and an angle grinder in depth. By the end, you should be able to tell which one you need and when, or if you should have both. For those in a hurry, the table below gives a quick overview of the comparison.

Summary

| RECIPROC. SAW | ANGLE GRINDER | |

|---|---|---|

| Cut materials: | plastics, wood, metals, ceramics, composites | metals, ceramics |

| Cutting capacity: | 5”…11” (16”) | 1”…2½” |

| Cut rate: | ~ same | ~ same |

| Kerf: | .05” to .08” | .06” and .015” |

| Blind cuts: | no | yes |

| Curved cuts: | yes | no |

| Noise: | quieter | louder |

| Dust: | coarse | fine, more hazardous |

| Sparks: | few…none | yes |

| Safety: | safer | less safe |

| Size: | larger, typ. 18” | smaller, typ. 14” |

| Cost: | ~ same | ~ same |

| Applications: | – soft to hard materials – multi-material cutting – demolition | – metal shop work – hard and very hard materials |

| PROS & CONS | |

|---|---|

| Reciprocating saw: + multi-material cutting + high cutting capacity + less noise, dust, sparks – only cutting – needs special blades for hard mats | Angle grinder: + hard material cutting + grinds, sands, polishes – not for soft materials – limited cut depth – more dust and sparks |

Recipro saw vs. Angle grinder: Cut materials

With the standard HSS or bimetal blades, a reciprocating saw can cut all plastics, wood and softer metals such as copper, aluminum, brass, and mild steel. The premium carbide-tooth blades extend the cutting capacity to stainless or hardened steels, and increase the blade life in cutting steel. Reciprocating saw blades are also available with a carbide or diamond grit, which allow the saw to be used for masonry, concrete, cast iron and most composites. With the correct blade, a reciprocating saw can these days be used to cut almost anything.

An angle grinder can cut most common metals already with their standard aluminum oxide cutoff discs. This makes an angle grinder a straightforward option for hard or tough materials, as you need to worry less of the type of disc you have mounted. That said, some very tough or hard materials like stainless steel, concrete and masonry may require cutoff discs with harder abrasives or tougher binder.

On the other hand, an angle grinder is not well suited to cutting soft materials like plastics or wood, as the standard cutoff discs tend to burn or melt the material instead of cutting it. While an angle grinder can cut soft materials with special saw blade or chainsaw-teeth discs, these are not very convenient or safe to use.

The table below lists some common materials that can be cut with both tools and the recommended blade or cutoff disc for each material. I have also included links to blades in Amazon for your convenience (Workshoppist.com is an Amazon Associate. As an Amazon Associate we earn from qualifying purchases.)

| CUT MATERIALS Material | RECIPRO SAW Blade type* | ANGLE GRINDER Disc type |

|---|---|---|

| Wood: | carbon steel/ bi-metal | N/A |

| Plastics: | carbon steel/ bi-metal | N/A |

| Aluminum: | bi-metal | aluminium oxide |

| Copper: | bi-metal | aluminium oxide |

| Mild steel: | bi-metal | aluminium oxide |

| Bolts: | carbide | aluminium oxide |

| Rebar: | carbide | aluminium oxide |

| Hardened steel: | carbide | aluminium oxide |

| Stainless steel: | carbide | aluminium oxide, tough adhesive |

| Cast iron: | carbide grit/ diamond grit | diamond |

| Masonry: | carbide grit/ diamond grit | diamond |

| Concrete: | carbide grit/ diamond grit | diamond |

| Fiberglass: | high-TPI carbide, carbide grit/ diamond grit | diamond |

| *(links to Amazon) |

Recipro saw vs. Angle grinder: Cutting capacity

The cutting capacity of a saw or other cutting tool means the maximum thickness of the workpiece that can be cut with the tool.

The cutting capacity of a reciprocating saw is determined in principle by the length of the saw blade you attach. Reciprocating saw blades are commonly available for many materials up to a length of 12”, putting the typical maximum cutting capacity of a reciprocating saw to an impressive 10…11 inches. Some special blades, notably those for brick, may go up to 16”, pushing the capacity still a few inches higher in these specific applications. Note that the cutting time increases with workpiece thickness, and may become a practical limit to cutting capacity before the blade length; this is particularly true with thick steel sections.

The cutting capacity of an angle grinder is limited by the reach of the cutoff disc. Unlike with a reciprocating saw, the disc size you can fit into an angle grinder is limited, and specific to the grinder model. Common angle grinder disc diameters are 4½”…7”, which translate to cutting capacities of 1-1/4”…2½”.

These capacities assume blind cutting from one side; if you have access to the other side of the workpiece, you can double the capacity to 2½”…5” by cutting from two sides. Exceptionally large gas-powered angle grinders may have discs up to 14” in diameter, giving you a cutting capacity of 6” in one-side and 12” in two-side cutting.

A the comparison shows, a reciprocating saw has a much larger cutting capacity than an angle grinder. The difference is most relevant in cutting large-diameter aluminum or steel pipe and profile: a long reciprocating saw blade allows you to reach and cut through in one go, while an angle grinder must go around the section.

Recipro saw vs. Angle grinder: Cutting rate

A reciprocating saw and an angle grinder have similar cutting rate into most metals. While an angle grinder usually has more power and a significantly higher cutting speed, it also has a wider kerf and a more energy-intensive grinding-type cutting mechanism. These limit the cutting rates achievable, so that a reciprocating saw is able to compete with an angle grinder head-to-head despite the lower power.

It should be noted that with both tools the cutting rate depends on the blade or disc you are using. For example, thin-kerf blades and discs cut faster than wider ones, and fresh blades faster than worn. The rate obviously also depends on the material and the size of the tool, so the subject of cutting rates is loaded with a lot of ifs.

To put some real numbers on the cutting rate, I did a short cutting speed test with a mid-range reciprocating saw and a mid-range angle grinder, both from the Makita 18V cordless lineup.

When fitted with a Bosch carbide blade and a .040” thin-kerf cutoff wheel, respectively, the reciprocating saw and the grinder both cut a AISI/SAE 316 27/32”x3/32” stainless pipe in practically the same time, about 7 to 8 seconds. The cutting times for a 13/16” steel chain link – a much heftier workpiece – were longer, but quite similar at 39 s and 44 s, respectively. The table below sums up the results.

| Material/Cutting time | Reciprocating saw Makita 18V & carbide blade | Angle grinder Makita 18V & .040” disc |

|---|---|---|

| AISI 316 27/32” pipe | 7…8 s | 7…8 s |

| 13/16” steel chain | 39 s | 44 s |

For comparison, I also tested cutting the pipe stock with a dull multi-purpose blade on the saw and a thicker cut-off wheel on the grinder. The cuts now took twice longer than with the better blade and thinner disc, showing that the accessories indeed make a big difference.

This test allowed me to conclude that the reciprocating saw and the angle grinder are pretty even in terms of cutting rate, at least as typical mid-range cordless models.

Recipro saw vs. Angle grinder: Cut geometry

Kerf

Kerf means the width of cut that a saw or other cutter makes, and is a central parameter in cutting. A narrow kerf is often desirable, as it means that a saw will waste less material and produce less chips and dust.

A reciprocating saw has narrower kerf on average than an angle grinder. The kerf of reciprocating saw blades varies from .05” to .08” (1.3…2.0 mm), with bimetal blades at the low end, carbide-teeth saws in the middle and low-TPI wood blades at the high end.

Common angle grinder cutoff discs, by contrast, have kerfs between .06” and .015” (2.1…3.7 mm), the narrowest produced by special “thin-kerf” discs. Note that when cutting hand-held, the kerf of a an angle grinder is invariably wider than the disc thickness because of the disc sides eating into the cut faces.

Blind cuts

A blind cut means one where the saw does not go all the way through the workpiece thickness from the side of cutting. Blind cuts are often necessary in making grooves, slots and pockets into a workpiece.

A reciprocating saw is very bad at making blind cuts because its blade is straight, cuts along its side, and needs space to move in its direction. You may be able to make some sort of blind cuts into soft materials with a reciprocating saw, they will not be very clean or consistent.

An angle grinder, on the other hand, can be used to make blind cuts, because the cutting edge of the disc can extend into the material and still perform the cutting action with rotary motion.

Plunge cuts

A plunge cut is a cut that does not start at the edge of a workpiece but instead somewhere in its middle. Plunge cuts are often necessary in making holes and cutouts.

Just as with blind cuts, a reciprocating saw is quite bad at plunge cuts, while an angle grinder can make them with ease. A reciprocating saw should preferably be assisted by drilling a pilot hole for the blade to start in.

Curved cuts

A curved cut is a cut where the cut line is not straight. A reciprocating saw is quite good in making curved cuts with most of its blades, as the blades are short and do not take much space to turn in the cut. An angle grinder cannot really make curved cuts as its discs are inside the cut line for a longer distance, and can barely turn at all without rubbing on the cut faces.

Recipro saw vs. Angle grinder: Practical considerations

Noise

The reported noise levels for both reciprocating saws and angle grinders vary widely, between around 80 and 110 dB(A), making a quantitative and representative comparison hard. Moreover, a single decibel number also does not tell the full story of the harmfulness or annoyance of power tool noise.

Subjectively, most people find the angle grinder noisier and more annoying a reciprocating saw. This experience may be down to the real decibels, the higher pitch or some other feature in the noise spectral content. While hearing protection is certainly needed with both tools, the higher noise level of the angle grinder may make the tool less comfortable than a reciprocating saw both for the user and the environment.

Dust

An angle grinder generates more and finer dust than a reciprocating saw. Fine dust is generally more easily spread and causes more health issues when it enters the body, making an angle grinder a bigger occupational health concern.

A reciprocating saw, by contrast, generates a much smaller amount of dust, and instead turns most of the removed material into larger chips. These chips fall fast onto surfaces and cause much less potential health damage than fine dust.

Sparks

In addition to dust, an angle grinder produces a lot of sparks when cutting ferrous alloys like steel and cast iron. While spectacular to watch, the fan of sparks emanating from the cutting point is a nuisance in that it may mar surfaces and causes a fire hazard.

Because of the sparks, using an angle grinder is often classified as hot work. This means that in a professional setting, angle grinder work may require extra precautions including a hot work permit and a fire watch, depending on the jurisdiction and industry.

A reciprocating saw, by contrast, produces few to no sparks even when cutting steel. Because of this, a reciprocating saw is better than an angle grinder from a fire safety point of view, and is often considered a fire safe alternative to an angle grinder.

Safety

Use of a reciprocating saw and an angle grinder both carry a risk of injury, but have slightly different hazard profiles. Both may cut your hand or other body part, kick back at you and send chips or the whole workpiece flying.

Because of the much higher speeds, the hazard potential of the angle grinder in all of these is somewhat higher. An angle grinder also poses a burn injury and fire hazard through the sparks.

The extreme hazard with an angle grinder is disc shattering, which may send high-velocity shrapnel towards the operator or bystanders and cause severe injury. Although this risk can be minimized by use of proper discs and a disc guard, it can never be completely ruled out.

A reciprocating saw, on the other hand, is slower and thanks to the lower kinetic energy the hazard level is noticeably lower. It does carry a risk of finger injury due to accidental operation when changing the blade.

Size

On average, angle grinders are slightly smaller and lighter than reciprocating saws. Naturally, both tools come in different size and capacity versions, but the mid-range reciprocating saw of a given manufacturer is usually substantially larger than the mid-range angle grinder.

To make the difference concrete, a popular mid-range cordless angle grinder by Makita is around 14” in total length and weighs less than 6 lb. For a compact reciprocating saw by the same manufacturer, these numbers are 17” and 8 lb. The size difference is only increased when you and the blade and the disc to the dimensions.

Cost

Reciprocating saws and angle grinders are fairly similarly priced.

While the tool prices obviously depend on the make and model, the cordless 18V lineup by Makita can again be taken as representative example. In this series, both angle grinders and reciprocating saws retail between $100 and $200, the exact price point depending on the model. The price difference is probably too small to sway the consideration either way.

Recipro saw vs. Angle grinder: Applications

So which uses is an angle grinder and a reciprocating saw good for? Let us quickly summarize the comparison:

Reciprocating saw:

- Multi-material cutting: A reciprocating saw is excellent for cutting different materials in a sequence or single workpieces composed of many materials. An angle grinder works well only with metals and some other hard materials, and would only melt or burn some of the materials.

- Soft material cutting: A reciprocating saw is much better than an angle grinder for cutting soft materials like wood, plastics and foam.

- Demolition work: A reciprocating saw is better for demolition work, where materials vary from soft to hard, and must be cut on spot. The sparks produced by an angle grinder cause a fire hazard, and may severely restrict its use a demolition sites.

Angle grinder:

- Very hard materials: An angle grinder can cut even the hardest of steels without issues, and can also be used for concrete, masonry and rock. A reciprocating saw cannot do these equally well, not at least without rare diamond grit blades.

- General metalworking: An angle grinder is better for general purpose use in a metal workshop, as it can not only cut, but also grind, sand, deburr and polish. A reciprocating saw functions properly only as a saw.

Do you need a reciprocating saw if you have a grinder?

An angle grinder will get most of your metal cutting done. If you are mostly cutting small cross sections in your metalshop or at a jobsite and do not mind the sparks, an angle grinder will probably suffice, and there is no need to get a reciprocating saw.

On the other hand, an angle grinder is not well suited cutting soft materials or large cross sections. If you often need to cut wood, plastics or large-diameter metal profiles, you should probably get a reciprocating saw. You should also choose a reciprocating saw for metal cutting in areas where the sparks from an angle grinder would cause a fire hazard.

Do you need a grinder if you have a reciprocating saw?

A reciprocating saw will be able to do most of your cutting for you, whether into wood, metals or composites. Although special blades may be required for materials like hardened steel or concrete, a reciprocating saw can handle them, and you would very rarely need an angle grinder for cutting as such.

However, an angle grinder is needed if you want to do any grinding, sanding or polishing, as these tasks cannot be done at all with a reciprocating saw.

Angle grinder or reciprocating saw – which to get first?

Whether you should get a reciprocating saw or an angle grinder first, depends on the type of work you plan to do with the tool.

If you are looking for a general-purpose cutter for use in your shop, around the house and at a jobsite, a reciprocating saw is almost always the right choice. It can cut more materials, has higher cutting capacity and is safer to use.

If, on the other hand, you are getting the tool exclusively for metalworking, you may want to prefer an angle grinder. The grinder will cut all steels without issues, and will also grind, sand and polish.

Conclusion

In this article, we have looked at the two popular cutting power tools – the reciprocating saw and the angle grinder – from the perspectives of material compatibility, cutting capacity, types of cuts possible, and practical concerns like noise and dust generation.

So how, exactly, did the two tools compare? A one-sentence summary would be that the reciprocating saw is the all-around powered saw for workpieces of any material, size and shape, while an angle grinder is the multitalent of metalworking in that it no only cuts, but also grinds, sands and polishes.

The reciprocating saw is the all-around powered saw for workpieces of any material, size and shape, while an angle grinder is the multitalent of metalworking in that it no only cuts, but also grinds, sands and polishes.

I hope this article has helped you understand the difference between the two tools in depth, and helped you decide which one to choose for each cutting task. Cut smart and cut safe!