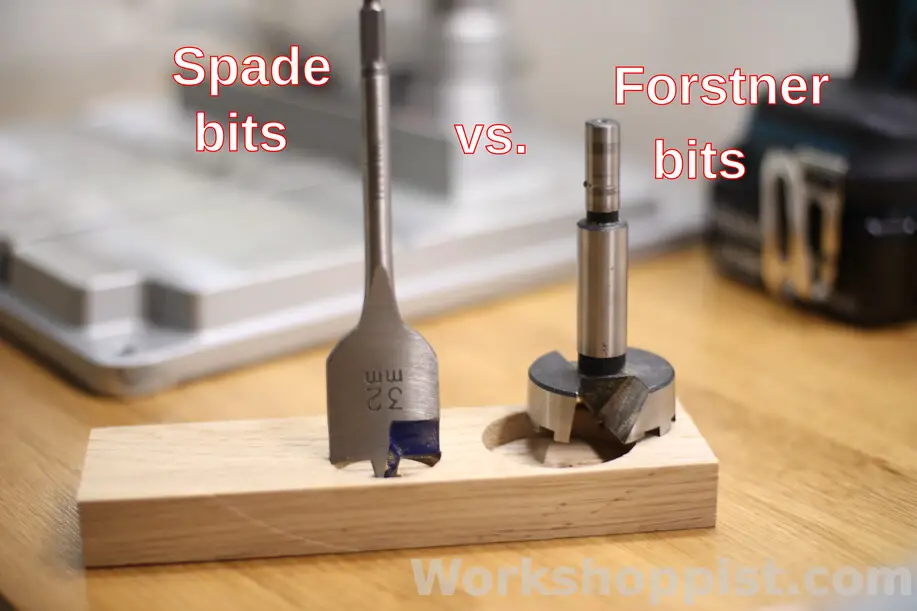

Spade bits and Forstner bits are two drill bit types that you can use to cut large-diameter holes into wood. So what are the two bit types for? Forstner bits are more expensive, but what are you actually paying for?

This article tells you how spade and Forstner bits differ. In short, spade bits are more compact and affordable, and allow you to easily drill short or deep holes up to 1½” in diameter, also handheld. Forstner bits are bulkier and more expensive but cut cleaner holes, leave the hole bottom flat and are available up to 4″ diameters. Spade bits are a jobsite/workshop must-have for lead-throughs and joinery, while Forstner bits are an accessory for cabinetry and fine woodworking, excelling at clean and precise through-holes and recesses.

Below we go through these differences one by one. For those in a hurry, I have also summarized the list in the table below.

| SPADE VS FORSTNER BITS | SPADE BIT | FORSTNER BIT |

|---|---|---|

| Sizes: | 1/4” … 1½” | 3/4’’… 4’’ |

| Hole depth*: | 5” | 2” |

| Hole bottom: | not flat | flat |

| Cut quality: | good | excellent |

| Self-guiding: | good | poor |

| Drive (typ.): | 1/4” hex | 3/8” plain |

| Physical size: | flat, compact | bulky |

| Cost: | $1…$3 per bit | $10 … $100 per bit |

| *no extender |

Difference 1: Forstners come in larger sizes

Spade bits are available in diameters from 1/4” to about 1½” (6…38 mm), a size range overlapping with that of standard spiral bits at the small end and auger bits at the large; the most common sets run from 3/8” to 1”.

Forstner bits are larger on average, with sizes starting at 3/4” and going up all the way to a whopping 4” (19…100 mm). Forstner bit sets usually include sizes between 1/2” and 1½”, although these bits are more commonly purchased individually.

Difference 2: Spades cut deeper

Spade bits cut holes up to 5″ deep with the standard shank, while Forstner bits can reach only 2″ without extension.

Spade bits come with a long shank and a hex drive; they offer plenty of reach for going through thick beams and are easy to extend if needed. Forstner bits, on the other hand, have a short shank, and are intended for drilling relatively shallow holes and recesses. While extenders are available also for Forstners, the plain shank drive makes extension less straightforward.

Difference 3: Forstners cut cleaner

Both spade and Forstner bits make clean holes, but Forstners holes are cleaner.

Forstner bits have long straight cutting edges and separate edge reamers, which leave the hole walls and bottom smooth as if planed. While unnecessary for most holes, such finish quality may be required in decorative items where the hole is left exposed (e.g. tealight holders).

Spade bits have much simpler cutting edges that are milled into the flat bit head. This leads to a relatively dull cutting angle close to 90 degrees and a slightly rougher cut than with the Forstner bit.

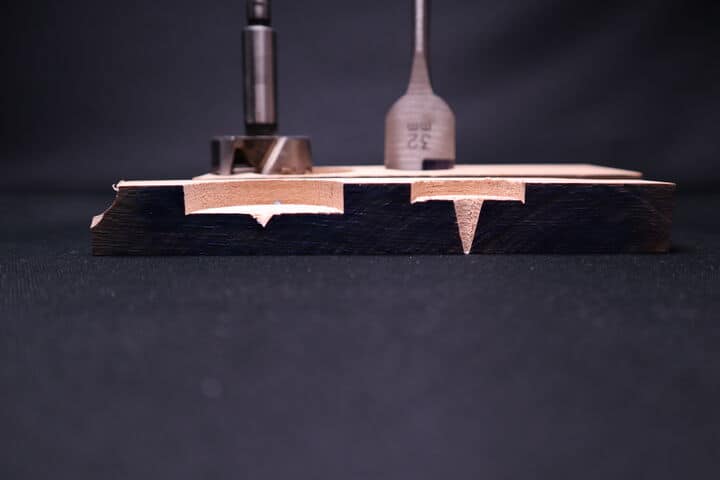

The different cut quality can be indirectly observed in the shavings produced by the two bit types, as illustrated in the image below.

Difference 4: Forstner holes have flat bottom

Forstner bits make a hole with a flat bottom, spade bits do not.

Spade bits have a long tapered tip and spurs at the sides. Though great for guiding, these features cut deep into the wood and leave the hole bottom uneven. The spike makes the spade bit unusable for blind holes in sheet goods as it almost certainly cuts through to the other side – not great in cabinetry.

Forstner bits only a very small center spike. While this makes them harder to start than spade bits, it also allows them to create holes with a flat bottom. Forstner bits are optimally suited for cabinetry and other applications where the clean flat blind holes are required.

Difference 5: Spades guide better

Spade bits self-center and are easier to start than Forstner bits, particularly when drilling handheld.

Spade bits are strongly self-centering with their spike and start a hole easily even on rough surfaces or at an oblique angle. The steady self-guiding also makes them well-suited for use with a hand-held driver.

Forstner bits have only a small spike and start well only on a flat and square workpiece surface. Although Forstners can be used hand-held, they should preferably be used with a drill press for secure guiding.

Difference 6: Drive

Spade bits usually come with the handy 1/4″ hex drive, while Forstner bits come with a plain shank.

Spade bits often have a 1/4” hex end to their shank, which allows you to use them with cordless drivers and impact drivers, or even with a quick release adapter, and always get a good grip for secure torque transmission.

Forstner bits almost always come with a somewhat thicker plain shank, usually 3/8” or 10 mm in diameter. While the diameter helps in getting a good grip, the largest Forstner bits at 2” and above require very large torques, and are prone to slipping in the chuck.

Difference 7: Spades are more compact

Spade bits are flat, and store very compact; actually, they are the clear winner in ease of storage across all drill bit types.

Forstner bits, by contrast, are not very efficient to store: they are neither slim like spiral bits nor flat like the spades. Whether you store them standing or on the side, they will take up around 4” x 2” x 2” per bit, or 4” x 2” x 1” with clever stacking.

Difference 8: Forstners are more expensive

Spade bits are simpler – essentially forged, milled and ground from a single steel piece – and very affordable: you can get the common 6- or 9-piece set of quality make at $10 to $15, and an extensive 12–13-piece set, including the larger sizes above 1”, at less than $30.

Forstner bits are complex and more expensive. Forstners are either welded or soldered from multiple pieces (shank, head, spike, main cutting edges and edge reamers may all be separate components) or a complex casting with much machining to finish. This leads to a relatively high price per bit, from around $10 per bit for entry-level brands up to $100 per bit for premium brands such as Fisch. Due to the high price, it may be practical to purchase Forstner bits one by one, each size when need arises.