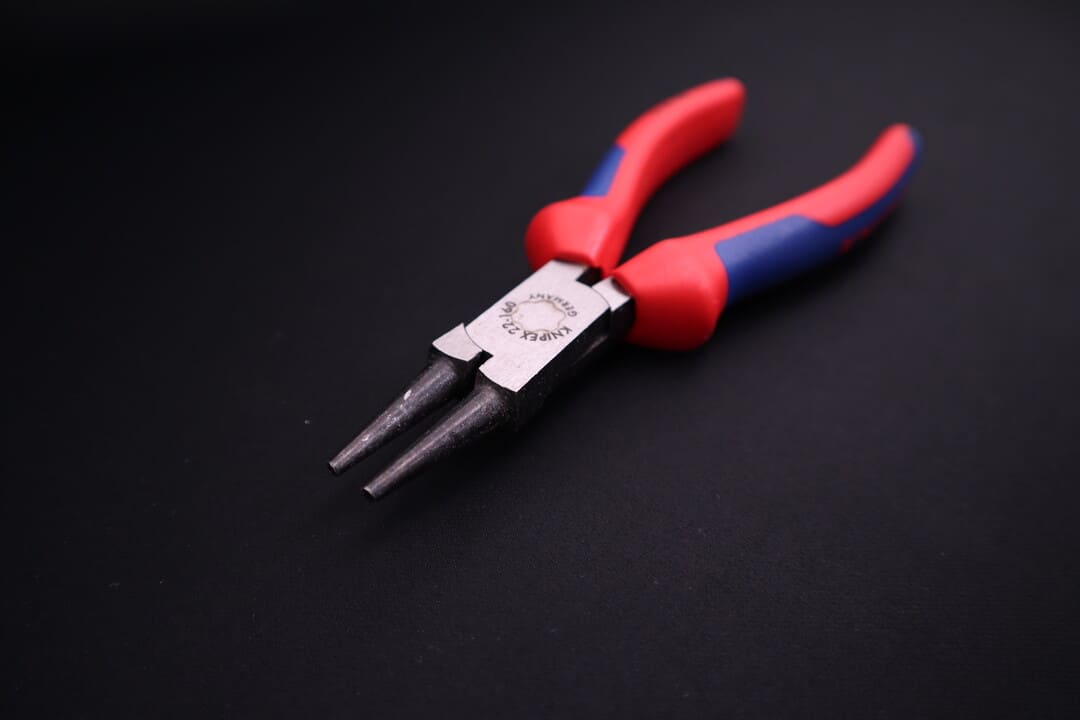

Round nose pliers are a peculiar-looking pliers type: their short round and conical noses are very different from practically all other pliers. With small slippery jaws and no wire cutters, these pliers do not seem too well equipped for either gripping or cutting. As their name gives no hints of their application, you might have wondered what are these pliers, and what are they really good for?

In this article, we are going answer these questions, and shed light on this less well known pliers type. The answer, in a condensed form: Round nose pliers are special-purpose pliers type intended for accurate bending of wire. The short tapering jaws of the pliers have a completely round cross section, and can be used to make smooth bends into wire with a controllable bending radius. Round nose pliers are superior to other types in wire bending applications where the requirements for bending precision or appearance are particularly high, such as jewelry, decoration, and fine mechanics.

Next, we will go through the special features of round nose pliers in more detail. I will explain how the features set these pliers apart from others, and make them excellent in their main task: bending wire. Whether you are a seasoned worker or a beginner, the information provided here should be helpful to you. So if you are interested in learning more, please read on!

(For those in a hurry, scroll to the bottom for a summary.)

1 Jaw geometry

Unlike other pliers which mostly have flat or semi-rounded jaws, the cross section of round nosed pliers jaws is circular. Although this feature sounds rather unexciting, it actually gives the type a crucial edge over other pliers, and is also unique enough to give this pliers type its name.

In general gripping usage, the round jaws are far from optimal: their smooth curved gripping surface does not allow for much traction, and is prone to slipping off the workpiece. The jaws are also quite slender compared to Lineman’s pliers, for example, and not very well suited for heavy bending flat bar and sheet metal.

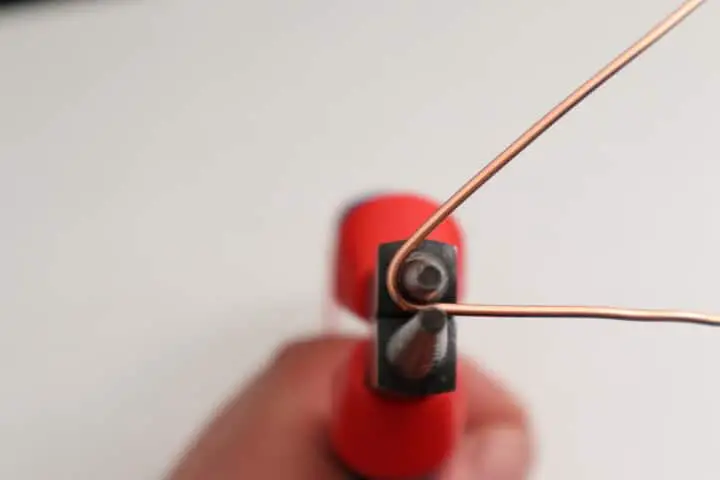

However, the round noses are excellent for what they are intended for: smooth and controllable bending of wire. The main reason behind this is that the round surface of the jaws can act as bending guide or a mandrel.

To understand how, consider this practical example: you grip a piece of wire sideways in the round jaws, and start bending up. As usual, the part of wire just outside the gripping surface is the one doing the bending. If the gripping surface ends in a sharp corner, as in Lineman’s pliers, this same part of wire, which can be called the process zone, would bend further and further, until it would make a corner almost as sharp as in the pliers jaws.

With round noses, however, the piece of wire will bend only up to the round jaw surface. Once the wire touches the jaws at a new spot, the bending in the preceding portion of the wire ends, and the process zone moves forward.

This bending process works continuously as you continue to wrap the wire around the round jaw. The end result is a wire bend with a constant curvature, i.e. a bend that is smooth and equally tight at all points.

2 Controllable bend radius

Round nose pliers allow you to accurately control the radius of the bend. Thanks to the taper, the jaws have a different curvature or radius at various distances from the joint, and you can select the radius of your bend by changing the spot on the jaws that you are using.

The roots of the jaws have a large radius .15” (3.8 mm), which translates to a low curvature in the bend. You can use the roots for making smooth, gradual bends or large-diameter loops. The tips, on the other hand, have a very small radius .061” (1.5 mm), and will make sharp bends and small-diameter loops. You also have all the positions and radii between the very tip and the root, so you can select any curvature between the minimum and the maximum you want.

The curvature control comes with a few reservations, though. First, while the bent wire roughly assumes the jaw radius at the point of bending, it will not do so exactly. Due to a phenomenon called spring-back, the bend left in the wire will actually be less sharp than the one in the jaws. The amount of spring-back you get depends mainly on the wire hardness: soft wire, such as copper, aluminium, silver and mild steel, will spring back only a little, while hard wire, like piano wire, will spring back substantially, and be difficult to bend predictably.

Second, there is a limit to the sharpness of the bend that you can make into a given wire.

On one hand, the amount of bending force that the round nose pliers jaws allow you to apply is limited, and depends on the part of the jaws you are using. The roots are relatively thick, stiff and strong, can transmit a high bending force, and therefore bend thick wire; the tips are more flexible, and suited only for lighter wire. (See ‘’Bending capacity’’ for more info.)

On the other hand, there is a physical limit to the sharpness of the bend, dependent on wire thickness and material. Thick and hard wire will not take a very sharp bend, no matter how you try. If you try to force it, the wire will snap.

3 Unlimited bending angle

An another advantage of round nose pliers is that the bending angle is essentially unlimited: you can make a 90 or 180 deg turn, or a full circle; you can also continue to multiple turns to make coils, spirals, and the like.

This feature is allowed by the round profile of the jaws. To see how, consider trying the same with a flat-nosed model, such as Lineman’s pliers. You will always be able to turn the first 90 degrees, but after that, the problems start. If you try to go beyond 90 deg., the nose side may get in the way, and prevent you from doing 180 degree turns, at least sharp ones. If you try a 360 degree turn, you are almost certainly in trouble: you have to increase the bend radius to fit the nose inside the bend, and the wide flat gripping surfaces will often fight against you, flattening the bend you already made.

With round nose pliers, by contrast, the nose is never in the way of bending. As the nose and the bend have the same radius, the wire will just neatly wrap around the jaw. Even the gripping surface is round and has the same radius, so you can grip a bend you already made without risk of flattening it.

While there are other thin-nosed pliers that have some of the same advantages in continuous bending, none of them are quite as good as round nosed pliers. Long nose and needle nose pliers also have thin noses which will not block the wire loops, but the nose cross section is only semi-round. Such jaws allow a constant radius bend only through the 180 degrees around the jaw back side; after this, the flat gripping surface will force a sharp 90 degree bend, followed by a flat section.

4 Excellent surface finish

Round nose pliers have one further advantage in wire bending: they are exceptionally gentle on the wire surface.

Most pliers jaws have serrated or knurled gripping surfaces. While the knurling does a lot to improve the grip traction, the multitude of pointed ridges often leaves marks or scratches on the wire. While these marks may not matter much in the average rough shop work, they may ruin the whole project in aesthetically sensitive applications such as jewelry.

Round nose pliers jaws, by contrast, are not only round, but also perfectly smooth. Such jaws do not scratch the wire, and allow you to work even with soft wire in jewelry and interior decoration without worrying about surface finish.

While they seldom scratch, round nose pliers may leave a smooth dent into the wire if you grip too hard. The reason for this is the very small contact area between the round jaws and the round wire. To avoid dents, you should limit your gripping force, particularly when working with soft wire.

5 Bending capacity

Round nose pliers are suited for working with light-to-medium gauge wire, and allow you to perform most of the easier work in jewelry, decoration, fine mechanics.

Compared to their size and agility, the bending capacity of round nose pliers is actually quite high. Although the round noses are relatively fine at the end, they are also relatively short and stubby. This means that the jaws are actually quite stiff relative to their thickness. The stiffness allows you to use the round nose pliers tips with much heavier-gauge wire than you could bend with needle nose or long nose pliers tips, for example.

However, round nose pliers are not suited for heavy-gauge steel wire. Due to the relatively small size, round nose pliers do not offer you the leverage for very strong gripping. They also do not allow you to apply high bending forces into the wire. You will have to leave such wire to bigger pliers or tube benders.

6 Versions

While round nose pliers are rather standard and have less variability than many other types, they are available in a few different sizes and configurations.

Sizes

Round nose pliers sizes range from 4½” to about 6½”. Often called “Jeweller’s Pliers”, the smaller round nose pliers between 4½” and 5” in overall length have very slender jaws, and are intended for very fine work in jewelry or fine mechanics.

The larger sizes from 5½” to 6½” have thicker jaws and are usually of a stronger build, are suited also for heavier wire. These sizes make for more general-purpose pliers, and unless you are working exclusively with very fine projects, I would recommend getting them first.

Jaw layout

There is some variation in also in the jaw layout:

1 Cutting edges: Whereas most round-nose pliers have a short flat gripping surface right above the joint and below the actual round noses, some models replace this grip with longer cutting edges. These cutters may be quite useful in some high-volume work, as they save you from an additional tool change. However, they also consume much of the high-leverage bending area, and these models are therefore best suited for lighter work.

2 Extra-long jaws: the typical jaw length for 6” round nose pliers is around 1”. Special versions with longer jaws are available, and provide improved reach, possibly wider bending radius range, more working room which may be useful at times. However, you should note that these improvements come at some cost to tip stiffness, and the long-jaw versions are not the best choice for making tight bends into stiff wire.

Some further variations and options to include:

- Asymmetric jaws: one jaw thinner than the other. This allows somewhat better bending radius control and range, but worsens the grip

- Return spring: useful in fine and detailed work, often found in small versions

- Polished jaws: improved finish that may be gentler on the wire surface, but also decreases the grip traction

- Chrome finish: increased corrosion resistance, advantageous in humid and condensing environments

There are also a number of pliers models with more substantial differences from the standard round-nose pliers design, that are sometimes called “round nose pliers”. However, I prefer to consider them as altogether different pliers types, and treat them in “Related pliers types”, see below.

Handles

The pliers handles may have the standard plastic dip coating, or a thicker multi-component grip. The standard grip should be just fine for most use, but if you are planning repetitive high-force bending, you should probably choose the thicker grips. Round nose pliers are available even with 1000V-insulated handles for work with or near electrical installations.

7 Applications

Thanks to its properties, round nose pliers are a good choice whenever your main task is bending light-to-medium gauge wire. Moreover, they are often the best choice if this bending must be done with very cleanly and precisely.

Some typical areas and bending tasks where round nosed pliers are at their best include:

- Jewelry: rings, earrings, small loops in general

- Home decor: coils, spirals, curved supports

- Mechanical: chain, springs

- Hobby: chain mail, lure making

Should you get round nose pliers?

If you need very controllable light-to-medium gauge wire bending even occasionally, I recommend getting a pair of round-nose pliers. Even if they are specialty pliers, they are rather affordable and add a lot of value in such work.

Otherwise, you are not likely to need round nose pliers. Most mechanical and electronic shop work is relatively rough: you do not have to control the bend radius, you are allowed to leave marks on the piece, and you usually bend to only 90 degrees. If you do not need neat or tight bends, you probably do not need round nose pliers either.

Personally, although I have used them to coil springs, I must admit that round nose pliers are one of the least used in my whole collection.

How much do round nose pliers cost?

Round nose pliers typically cost between $15 and $30. The smaller 4½” versions are often below $20, the standard 6” around $20, and special models with cutters, chromed jaws, extra-long jaws, or 1000-Volt insulation grips closer to $30.

Relative to their size, round nose pliers are averagely priced: they are somewhat more expensive than the more common and high-volume long nose or combination pliers, but cheaper than needle nose or very rare gripping pliers types.

You are probably able to find round nose pliers from less-known brands at a clearly lower cost than indicated above – some pairs are available even in sets that cost less than $10 in total. While some these low-cost options may work just fine in what you are going to use them for, if you want to be sure, I recommend sticking to established brands.

Related pliers types

Half-round nose pliers

Recognizing that only one jaw is used at a time as a bending guide, some pliers models have one jaw with a fully round cross section as in round nose pliers, but the other with a flat gripping surface and a rounded back, similar to the jaws of long nose pliers. Yet another variation has one jaw flat, but the other jaw half-round with a rounded gripping surface and a flat back – the opposite of long nose pliers.

These special versions may offer some advantages to professionals, but if you do not know that you need them, you are probably better off with standard round nose pliers.

Stepped-jaw pliers

Similar to round nosed pliers, but with jaws tapering in three discrete steps. These models make hitting a certain bend radius easier, since the radius does not change even if you are not using exactly the correct spot on the jaws. However, these pliers typically include only 6 different radii, and thus offer only a limited selection of bend tightnesses.

Long and needle nose pliers

The terms “round nose pliers” and “half-round nose pliers” are sometimes used to refer to long nose and needle nose pliers. These pliers indeed have half-round jaw cross sections: the gripping surfaces are flat, and the backs rounded. However, these pliers models are quite different in function from round nose pliers and also have more established names. This use of the term is confusing, and I would rather avoid it.

Summary

The main characteristics of round nose pliers discussed here are summarized in a table and a Pros & Cons list below.

| Round nose pliers properties | |

|---|---|

| Primary use: | bending wire |

| Other uses: | – |

| Bending radii (standard): | .061”…0.15” (1.5…3.8 mm) |

| Bending angle: | unlimited |

| Applications: | jewelry, fine mechanics, decor |

| Sizes: | 4½”…6½” |

| Price: | $15…$30 |

Pros:

- excellent for bending wire

- controllable bending radius

- gentle on wire surface

- affordable

Cons:

- restricted uses

- not for heavy-gauge wire