Dremel and other rotary multi tools are one of the most versatile pieces machines in your workshop. You probably have seen one, used one and maybe own one. But have you ever stopped to think which way the tool actually spins?

In this short post, we are going to look at which direction a Dremel rotates, why, and why does it matter. In short, Dremels and other rotary multitools spin clockwise when viewed from the side of the tool body. The choice affects the direction of exiting cutting debris and kickback, the ease of tool holding due to counter-torque, and handedness of threads on the tool.

Below, we are going through all of this in more detail. We will also look at whether any rotary tools spin counter-clockwise or could be made to do so. If you have ever wondered why a Dremel throws the swarf at you, and what the alternatives are, read on!

Dremel spins clockwise

Dremel and other multi tools spin clockwise. As rotation directions can be difficult to express unambiguously, this point deserves elaboration.

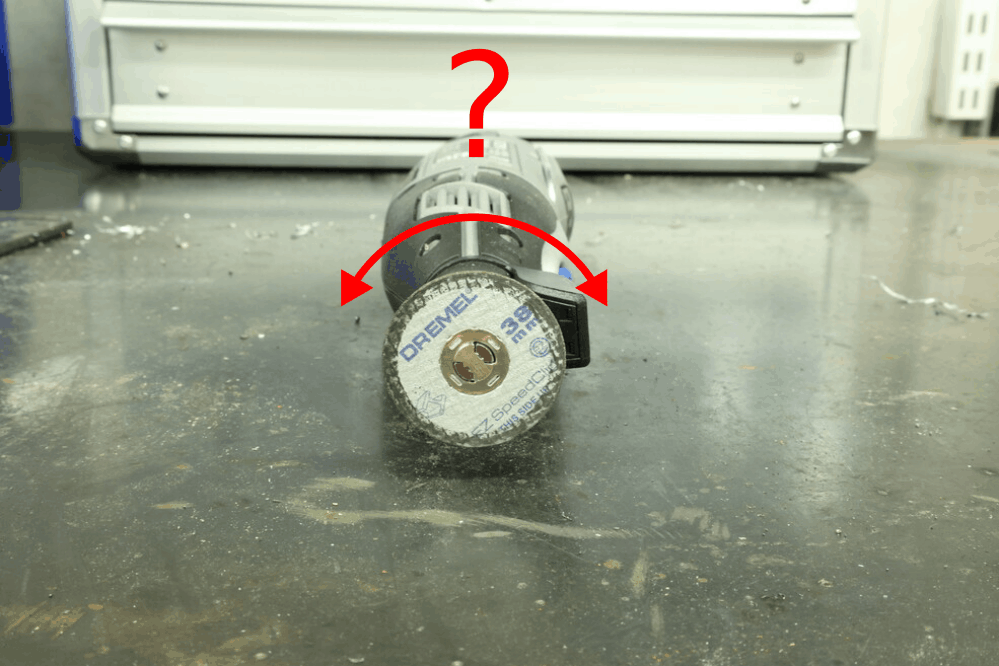

To be exact, the shaft of a Dremel or other rotary multitool rotates clockwise when viewed from the side of the tool body. If you view the shaft from the bit side, the rotation appears to be counter-clockwise. The image below illustrates the rotation direction quite unambiguously.

What the clockwise rotation means, is easiest to remember with a screw analogy: a Dremel rotates the way a screw tightens. I should add that here we assume the screw to have a right-handed thread, as the vast majority of them do. Although impractically fast and uncontrollable as a screwdriver, a Dremel could be used to tighten a standard right-hand threaded screw.

Why do rotary multi tools spin clockwise?

The reason why tool manufacturers have decided to use the clockwise rotation direction also for rotary multitools like Dremel is probably a balance between a few practical factors and convention.

Benefits of clockwise rotation

For right-handed users, the clockwise spin offers quite a few benefits. To start with, the torque generated by the cutting forces is easier to counter for most users when they have to hold down instead of up. Second, the kickback that results from a possible binding of a cutting disc or other tool to the workpiece will be directed away from the user, which is certainly the safer direction.

On the side of the blade, the clockwise spin also tightens both the standard right-hand threaded blade mounting screw and the collet nut in case of slip, and makes loosening of the blade during cutting very unlikely.

Last, a clockwise rotation direction makes the Dremel compatible with standard right-handed drill and milling bits. If the direction were reversed, the tool would need purpose-made left-handed drill and milling bits.

Downsides of clockwise rotation

There is one clear downside of the clockwise rotation: the blade will often throw the chips directly at the right-handed user who cuts or grinds in the normal working position, with the tool sideways in front. This is illustrated in the image above.

The chip trajectory will actually depend on the exact contact location between the blade and the workpiece. Sometimes you can direct the stream of debris downwards by shifting the contact to the front of the workpiece. In most cases, working ergonomics or visibility requires the contact to be on top of the workpiece, which means that the chips will be coming your way.

| Clockwise rotation | Counter-clockwise rotation |

|---|---|

| + counter-torque easier to apply + right-handed screws tighten + tool kickback away from user + standard drill and milling bits work – chips fly at user | – counter-torque more difficult to apply – right-handed screw loosens – tool kickback towards user – drill and milling bits do not work + chips fly away from user |

The compromise

For the tool manufacturers, the benefits of clockwise rotation seem to have outweighed the single drawback, and the clockwise rotation has been universally adopted.

Not everybody sees the balancing situation the same, though. For many users, getting the chipstream away from their lap would have been the main thing, and the tool supporting, thread direction and kickback just things to be dealt with somehow.

Dremel rotation and left-handed users

This far we have discussed the benefits and drawbacks from the point of view of right-handed users. How about left-handed people?

The truth is that for a left-handed operator, the pros and cons of clockwise rotation are exactly the reverse of those for a right-handed user. The clockwise rotating tool will throw the debris away from the left-handed user, but the counter-torque is more difficult to apply and the kickback will be towards him or her. The only thing that remains the same is the collet nut and mounting screw tightening, as they do not depend on the handedness of the user.

The different handed users adds to the conundrum the tool manufacturers face: whichever rotation direction is chosen, some users are going to get the one set of downsides, and others the other.

Can you reverse the rotation direction of rotary multitools?

As many users are unhappy with getting the cutting debris to their lap in the most convenient working position, there is constant talk on the forums of reversing the rotation direction of Dremels.

Technically, modifying a Dremel so that it spins “backwards” is certainly possible. However, such modification is not recommended, because many parts of the tool will no longer work properly.

Two examples of spots that become a problem are the collet nut and the blade mounting screw on the tool. Both have a right-handed thread, and for a reason: if the connections are a bit loose and there is some slip during operation, the slip itself will tend to tighten the connection.

With the rotation direction reversed, this slip will loosen the connection further and likely prevent operation fast. Depending on the model, there may be further right-handed threaded connections along the tool shaft line, which become possible points of failure.

Another possible issue is with cooling: the impeller on the tool shaft may have curved blades and be designed for a certain rotation direction only. If the direction is revers, the airflow will not be as effective in cooling the tool, which may lead to excessive heating.

If you still decide to go ahead and reverse the rotation direction, please remember that your drilling and milling bits will no longer work with the tool.

Are there rotary multitools that run counter-clockwise?

To my knowledge, there seem to be no Dremels or other rotary multitools that would rotate counter-clockwise when looking from the side of the tool body. Some claim that the Proxxon IBS/E would do so, but owning one, I can tell it rotates clockwise just as all other multitools.

Could there be a multi tool that rotates counter-clockwise?

The truth is that nothing stops you from designing and building a rotary multi tool which spins counter-clockwise. If the handedness of the threaded connections is reversed and the rotation direction taken into account in the tool cooling, a counter-clockwise multi tool should work just as a clockwise one.

Could there be a multi tool that rotates in both directions?

You could also design a rotary multitool which allows the rotation direction to be switched, just as on a cordless driver. This would require only minor changes to the motor control, but more major ones in the tool-holding. The collet chuck should be redesigned to lock securely with both rotation directions, or swapped altogether for a three-jawed chuck. Further, the toolholders for cutting discs and the like should use a locking mechanism like the Dremel EZ Lock that does not rely on a tightened screw.