Ripping chains are often claimed to be essential in chainsaw milling in lowering the saw engine loading and leaving a smoother cut. But what exactly are these chains and how do they differ from “regular” chainsaw chains?

In this article, I give you an overview of what ripping chains are, how they work, and when they are worth using. Shortly put, a ripping chain is a special-purpose chainsaw chain intended for cutting logs or lumber along the grain. Compared to a regular chain, a ripping chain has a lower cutter sharpening angle of 5 to 10 degrees and may also employ special cutter sequences. This allows a ripping chain to cut stabler, produce a smoother finish and draw less power when cutting along the grain. Ripping chains are particularly suited for chainsaw milling but do not work well in cross-cuts.

Next, we start by delving into how a ripping chain is constructed and the ways in which it differs from regular cross-cut chains. We will continue by going through the types and specs of ripping chains, and I will explain how you should match a ripping chain to your chainsaw. We will also take a quick look at the different manufacturers and where you can find these specialty chains. If you are interested in understanding ripping chains or perhaps getting one for your saw, this article should get you started!

Please also check my article on how you can make a ripping chain for instructions on converting a regular chain for chainsaw milling.

Ripping vs. Cross-cutting

Cross-cutting means cutting across the wood grain. Most of the time, chainsaws are used for cutting wood across the grain. Whether logging, pruning or cutting firewood, you are almost always running the saw cross-wise through the tree trunk, or with lumber, a part of it.

For this reason, the normal or regular chainsaw chain is actually a cross-cut chain optimized cutting across the grain.

Ripping means cutting along the wood grain. When you are running the saw along the length of a log or piece of lumber, you are cutting wood along the grain and therefore ripping.

For more info on ripping vs. cross-cutting, see my article on the topic.

How does a Ripping Chain differ from a Regular Chain?

Overall, a chainsaw ripping chain is relatively similar to a regular cross-cutting chain in construction.

Ripping chains differ from regular (cross-cutting) chains in shape and arrangement of cutters, i.e. the “teeth” of the chain:

Difference 1: Lower tooth angle

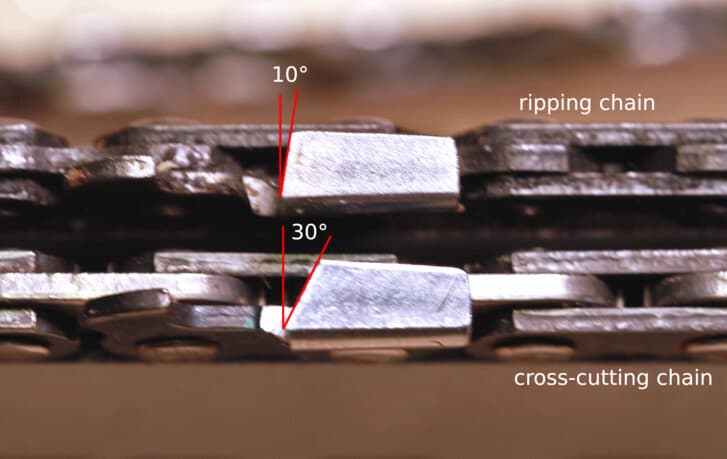

Ripping chain cutters are sharpened to lower angle than those in cross-cutting chains. Looking from above, you can notice this by the cutter top plate front edge having only a very mild backwards sweep and being almost perpendicular to the cutting direction. A typical sharpening angle for ripping chain cutters is 5 to 10 degrees, while cross-cut chains are sharpened to around 30 degrees.

Difference 2: Higher depth gauges

The depth gauges in ripping chains are usually higher than those in cross-cut chains. These gauges, also called rakers or depth stops, precede the actual tooth in each cutter link, and serve the purpose of limiting the depth of cut. The higher rakers effectively prevent the ripping chain cutters from biting as deep as those in cross-cut chains. In practice, this difference is difficult to see without measuring it.

Difference 3: Scoring teeth

Some ripping chains, notably those by Granberg, may have every other cutter pair replaced by scoring cutters that are narrower than the standard ones. These cutters help in phasing the cut so that each tooth has to clear only one quarter of the full cut width instead of one half. In such chains, the scoring cutters take care of the left and right edges of the cut, and the following full-width clearing cutters handle the middle.

How does a ripping chain work?

So why are ripping chains like they are? What is the point of these differences?

In principle, a ripping chain works just as a regular chainsaw chain: it cuts wood with each of its teeth. However, the small constructional differences help a ripping chain to cut less aggressive and produce a smoother result. Let us break this down:

1 Less side force

The lower tooth angle of the ripping chain cutters does not push the teeth as much outwards as in a crosscut chain. This is just what you want in ripping, since now the top plates of the cutters are doing the heavy work of cutting the wood fiber; the side faces are just severing the much weaker cross-grain bonds, and do not need a lot of push to stay in contact.

In cross-cutting, it is the side plates and shoulders that are doing the heavy fiber cutting. A regular chainsaw chain has the 30 degree sweep in its top plate edge to counter the cutting resistance the side plates face and keep them in contact with wood.

Now, if you use a regular, cross-cutting chain in ripping cuts, the swept top plate edge is going to create a lot of side force that tries to spread the teeth outwards. As the side face of the cutter has an easy job, the side force will actually be able to spread the cutter links out. This is not what you want: it will widen the kerf, take more power, and lead to an unstable cut that leaves a ripply finish on the cut faces.

2 Lower chip load

The higher depth gauges in a ripping chain limit the cut per tooth to a shallower depth than in a standard cross-cut chain. This means that each of the cutters takes a thinner chip and does not try to bite in as deep as it otherwise would.

A lighter chip load is advantageous since it lowers the cutting force per cutter and helps your saw cope with the heavy task of ripping. To see why, consider that in ripping, you are usually engaging almost the full width of the log with the chain. This brings many more teeth into contact with the wood at the same time, and will easily stall even a powerful chainsaw if each cutter tries to bit too deep.

Advantages of ripping chains

So why should you exactly use a ripping chain instead of a regular cross-cutting chain in ripping cuts? Let us bring the differences in mechanics listed above to the level of practice:

- Stabler cutting: a ripping chain allows long rip cuts to proceed stably without stalling the saw or burning the wood

- Lower power requirement: by lowering the chip load and keeping the kerf narrow, a ripping chain takes less power to run. This helps prevent saw overheating and may allow you to use a smaller chainsaw.

- Smoother surface: a ripping chain will produce a smoother surface finish on the cut faces by promoting stable chain running and reducing splay.

What is a ripping chain used for?

As the name suggests, a ripping chain is intended for ripping cuts, i.e. cuts along the wood grain. In most cases, the grain runs along the length of the piece of wood, so ripping chains are meant for any cut along the length of a log or a piece of lumber.

1 Chainsaw milling

The most common application of ripping chains is chainsaw milling, which basically means sawing a log to lumber using a chainsaw (instead of a sawmill). Chainsaw milling typically uses lightweight portable guide systems for the saw, and allows you to cut a log into planks, boards and beams literally in the middle of a forest. A ripping chain is a central accessory in chainsaw milling, as it both makes the heavy cut lighter for the saw and improves the surface finish of the lumber produced.

2 Resawing lumber

An another possible application of ripping chains is resawing lumber to smaller sizes. While resawing with a chainsaw is more wasteful and less accurate than with more conventional equipment, it works just fine, and may be your only choice in a pinch. Although these resawing cuts are usually lighter than those in chainsaw milling, a ripping chain is still useful as it produces a much smoother finish on the resawn pieces.

3 Any other ripping cut

While chainsaw milling and resawing cover most of the ripping chain use cases, wood may be sawn along the grain for some other purposes too. A ripping chain is preferred for all such cuts when the cut is long and wide or a goodsurface finish is important.

Ripping chain vs. Skip chain

Skip chains are an alternative chain type that can be used in ripping cuts. These chains have cutter links with the regular cross-cutting tooth geometry, but just have less of them, with more space between the cutters; that is, they “skip teeth”.

By having fewer cutters in the chain, skip chains lower the number of teeth in contact with the log at any given time. This reduces the total saw power requirement, and makes the chain lighter to run, even though the aggressive cutter geometry remains. The reduced running power makes skip chains better for ripping cuts than regular cross-cut chains are.

Skip chains and ripping chains are similar in that both reduce the power required to run the chain. Whereas a ripping chain does this by reducing the chip load at each cutter, a skip chain just reduces the number of cutters.

So are skip chains and ripping chains equally good in ripping cuts?

No, not really. While a skip chain does solve the power draw part of the problem, it still has the cross-cutting tooth geometry, which is not optimal in rip cutting. Because of the cutter geometry, a skip chain does not run as stable as a ripping chain, and leaves a wavy surface finish on the cut faces.

That said, ripping cutter geometry and tooth skipping can be combined in the same chain –in fact, this is what Oregon does in some of their ripping chain models.

Ripping chain properties

Ripping chains come in a few different variations and with a small number of specs that you should pay attention to when choosing a chain for your use. To help you get a grip, I have assembled all the central properties in the table below, along with some typical values:

| RIPPING CHAIN | Options (typ.) | Comments |

|---|---|---|

| Cutter sequence: | standard 2/2 scoring+clearing semi-skip, full skip | sequences can be combined |

| Cutter geometry: | semi-chisel full-chisel half-width (scoring) | semi-chisel standard, kick-back hazard w. full-chisel |

| Cutter angle: | 0…20 deg. | 5…10 deg. typical |

| Chain pitch: | .325”–.404” | 3/8” common, see size table |

| Chain gauge: | .050”–.063” | see size table |

| Drive link count: | 66…200 links typ. | match to bar |

The jury is still out on the relative merits of different ripping chain types. Rationally, one could expect the scoring/clearing and skip sequences to outperform the standard sequence, but my own experience is too limited to tell the difference. The same goes for cutter angle and geometry: semi-chisel and 5 to 10 degrees sharpening angle are common and definitely work, but I could not find any data on whether they are actually optimal.

The most important thing is to get a ripping chain that matches your saw – see next section.

Matching a ripping chain to your saw

As with all chainsaw chains, when shopping for a ripping chain you must select a chain model that matches your saw. The main parameters to match are pitch, gauge and drive link count.

1 Pitch

First, check the chain pitch that your powerhead and guide bar are compatible with. A surefire way of doing this is to check you saw and guide bar specifications; alternatively, you may the pitch from your existing chain. Your new ripping chain must have the same pitch as your powerhead and guide bar sprockets.

Note: Ripping chains are not currently available for the small chain pitches 1/4” and 1/4”LP (Low Profile, Picco) from any manufacturer, and for 3/8”LP only from Granberg.

2 Gauge

Next, check the chain gauge of your guide bar. You can do this by checking your guide bar specifications (sometimes also directly printed on the bar). Your new ripping chain must have the same gauge as your guide bar.

Note: Ripping chains are not currently available for the smallest .043” gauge (Micro) from any manufacturer.

3 Drive link count

Now it’s time to match the length of the chain to your guide bar. This is usually done by counting the drive links in the chain. The proper number of drive links is determined by the powerhead–guide bar combination, and you can check it from the saw specifications. Alternatively, you can count the links in your existing chain. Your new ripping chain should have the specified number of drive links.

Available ripping chain sizes

Ripping chains do not come in every size you can find regular chains in. Instead, they in a handful of pitch–gauge combinations, with emphasis on the larger sizes. The table below shows the available combinations from different manufacturers which I was able to find.

| GAUGE: .043” | .050” | .058” | .063” | |

|---|---|---|---|---|

| PITCH: | ||||

| 1/4’’LP | – | – | – | – |

| 3/8’’LP | – | Granberg | – | – |

| 1/4’’ | – | – | – | – |

| .325’’ | – | Granberg | Granberg | Granberg Carlton |

| 3/8’’ | – | Granberg Oregon Woodl.Pro | Granberg Oregon Woodl.Pro | Granberg Oregon |

| .404’’ | – | – | – | Granberg Oregon Woodl.Pro |

Oregon ripping chains have by far the best online availability. I have listed the Oregon ripping chain models in the table below and included a link to Amazon. (Workshoppist.com is an Amazon Associate. As an Amazon Associate we earn from qualifying purchases.)

| OREGON RIPPING CHAINS 3/8″ pitch | Lengths DL(in)* |

|---|---|

| RipCut™ 72RD ⋅ .050″ gauge | 62(16”) 70(20”) 72(20”) 81(24”) 84(24”) 91(28”) 105(32”) 114(36”) |

| RipCut™ 73RD ⋅ .058″ gauge | 68(18”) 72(20”) 84(24”) 93(28”) |

| RipCut™ 75RD ⋅ .063″ gauge | 84(24”) 105(32”) 114(36”) 115(36”) 135 |

| *(links to Amazon) |

Ripping chain brands

Ripping chains are offered ready-made in 2020 by three major brands: Granberg, Oregon, and Woodland Pro. Additionally, there are still some aftermarket Carlton ripping chains available, although the brand itself no longer seems to market them.

Granberg is probably the biggest name in ripping chains. Granberg employs the scoring–clearing cutter sequencing in their chains, which should make them lighter to run than even conventional ripping chain models. The company carries ripping chains for pitches .325, 3/8, 3/8 Low Pro, and .404 and gauges .050, .058 and .063, so you should be able to find a model to fit your saw (for details, see the size table above).

Oregon is a big player in chainsaw chains and accessories and also carries ripping chains in their selection. Their RipCutTM chains have special cutter geometry (“Micro Chisel”), and some models also combine skip sequences to ripping cutter geometry to create light-to-run ripping chains. Oregon offers ripping chains in pitches 3/8” and .404”, but not .325” or 3/8” Low Pro (for details, see the size table above). Note that Oregon specifies that their ripping chains are suited for ripping only and should not be used hand-held.

Woodland Pro is a chainsaw chain manufacturer with some ripping chains in their selection. In 2020, these chains are listed by Walmart, but I was unable to find much detail on the construction or sizes. It seems that at least three sizes are available (see size table above).

Carlton is a chainsaw chain manufacturer which used to carry ripping chain models in its selection. In 2020, Carlton ripping chains seem no longer to be offered, and can only be found in Ebay. Carlton continues to make appearances in ripping chains, though, as links in Granberg ripping chains.

Stihl currently carries a single ripping chain model (33 RMX, 3/8″ pitch, .050″ gauge) in its selection, but the availability seems very patchy. Stihl chains adapted for ripping can nevertheless still be found at some retailers, and also as accessories to chainsaw mills from Logosol.

Other manufacturers?

Of the other major players in the chainsaw industry, Husqvarna lists two ripping chain sizes, available in 100 ft reels. However, these chains can be found only on their Australian websites; there are no corresponding listings on the US or UK sites.

Should you get a ripping chain?

As we have learned in this article, a ripping chain has many advantages over your regular cross-cutting chain in ripping cuts. But is a ripping chain really worth its price, and when should you get one?

For chainsaw milling, a ripping chain is a highly recommended piece of gear: it will make your cuts stabler and smoother, and reduce the risk of saw overheating. Further, the $20 to $50 you have to pay for a ripping chain is not too much compared to the $200 to $400 you will pay for a chainsaw mill.

For occasional ripping cuts along the grain, such as those in carving of working with timber, a ripping chain is not really necessary, or even recommended. In these tasks, you will be going between ripping and cross-cutting all the time, so that swapping the chain to match the cutting direction will be impractical.

Ripping chain FAQ

Can you DIY a ripping chain?

You can also make a ripping chain yourself from a regular cross-cutting chain – see my full article on the topic. In summary, to make a conventional ripping chain:

- Get a regular (cross-cutting) chain with a semi-chisel cutter geometry.

- Grind the cutters to a sharpening angle of 10 degrees.

- Optional: Cut half of the top plate width from every second cutter pair to make scoring teeth

The process takes quite some effort and you are probably better off using a ready-made ripping chain. But if none are available, a DIY ripping chain should serve you just as well, provided you are willing to take on the grinding required.

Do ripping chains cut faster?

This depends on the cut type:

Ripping chains are faster than cross-cutting chains in ripping cuts, i.e. cuts along the wood grain. Most cuts along the length of a log or a piece of lumber fall in this category. A ripping chain is fast in ripping cuts as it keeps the kerf narrow and cuts efficiently despite a long chain contact. That said, ripping a small log with a powerful saw may sometimes be faster with a cross-cutting chain due to the higher depth of cut – if power is not limiting, a cross-cut chain is faster.

Ripping chains are slower than cross-cutting chains in cross-cuts, which cover the vast majority of chainsaw use. The low sharpening angle and special cutter sequences of ripping chains are not well suited to cross-cutting.

Can you cross-cut with a ripping chain?

Cross-cutting with a ripping chain is possible but ineffient and not recommended. Further, some manufacturers (Oregon, Husqvarna) specifically forbid using their ripping chains for cross-cutting.

The main reason for the inefficiency of ripping chains in cross grain is the low sharpening angle, which leaves the side plate and shoulder cutting edges relatively blunt. While not a problem in cutting along the grain, this is a serious issue in cross-cutting, where these portions of the cutter should do the heaviest fiber-cutting work.

Which ripping chain should I get for chainsaw milling?

If you are planning of getting yourself a chainsaw mill from Granberg or Logosol, you may be wondering what kind of a ripping chain works best with these mills.

The short answer is that any ripping chain should be good for chainsaw milling, and perform much better than a regular cross-cut chain – provided, naturally, that it fits your saw. Indeed, chainsaw milling is the number one application of ripping chains, so most of them are designed exactly for this purpose.

That said, you may find some ripping chains to work better with your chainsaw mill than others. If the logs are large or your saw a bit short of power, you may want to prefer ripping chains with skip or scoring/clearing cutter sequences, such as those from Granberg or Oregon. With small logs and a powerful saw, the ripping chain type is less of a concern.

Do ripping chains need a special bar?

Ripping chains do not need a special guide bar, but work with any regular guide bar – provided that the chain pitch, gauge and length match. For more info, see the section above on matching.

Getting a longer guide bar & ripping chain combination for chainsaw milling is often advisable, though. Most chainsaw mills take up some space at the bar root and tip, reducing the effective cutting length of the bar.

Ripping chain vs. Full-chisel chain?

Ripping chains and full-chisel chains cannot really be compared. Full-chisel refers to the cutter shoulder shape, whereas ripping refers to a specific chain application. Some ripping chains are full-chisel, others are not. Some full-chisel chains are also ripping chains, though most are cross-cutting chains.

See my article on full-chisel vs. semi-chisel chains for more information.